Currently, the challenges associated with thermoplastic materials in the rotational casting method have been addressed through a new rotational casting technique that utilizes polyurethane instead of other materials.

|

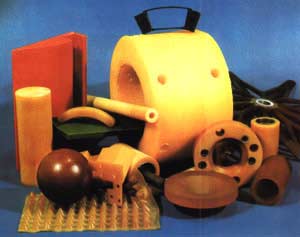

Polyurethane (Photo: trekollan) |

The current thermoplastic rotational casting method is conducted at high temperatures to maintain the viscosity of the thermoplastic material at a sufficiently low level for proper distribution within the mold. This method is energy-intensive, and the longer rotation times significantly increase costs.

Peter Orywol, a polyurethane expert at Bayer, states that using polyurethane is a technological advancement that brings numerous benefits. The two-component liquid mixture can be easily distributed into molds at room temperature and reacts at relatively low temperatures. As a result, this method significantly reduces the energy consumption required for production and the rotation time.

All properties of polyurethane, such as hardness, impact resistance, and elasticity, can be precisely adjusted by selecting the components of polyurethane, without the need for additional plasticizers.

Polyurethane also tends to be harder than thermoplastics of the same thickness, offering better abrasion resistance, decay resistance, high-temperature stability, and excellent adhesion. Some products can be used at temperatures of up to 180°C.

TRUNG KIÊN