Have you ever opened the hood of your car and wondered what happens inside its engine? You might not be curious and may not want to know the details. However, when buying a new car, you certainly need to understand what 3.0 V6 or 2.4 G means. What are “Dual overhead cams” or “tuned port fuel injection”? To answer these questions, let’s explore how car engines work.

Understanding How Car Engines Work

The purpose of a car engine (commonly powered by gasoline or diesel – referred to as an engine) is to convert the energy generated from the combustion of fuel into mechanical energy that can move your vehicle. Since the combustion process occurs within the cylinder, this type of engine is called a internal combustion engine.

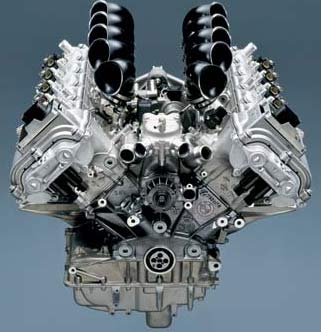

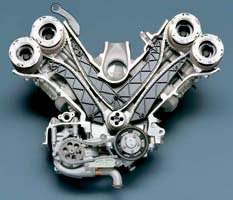

Maybach 57 Engine

In fact, there are also external combustion engines. For example, steam engines used in classic trains are a type of external combustion engine. Fuels such as coal, wood, and oil are used in steam engines to generate heat, boiling water into steam, which then creates motion within the engine. The efficiency of internal combustion engines is higher than that of external combustion engines (meaning that for the same distance, internal combustion engines consume less fuel than external combustion engines), and moreover, internal combustion engines are much smaller compared to equivalent external combustion engines. This is why cars use internal combustion engines.

Four-Stroke Engine Operation Principle

Most modern cars use piston-type internal combustion engines due to several advantages:

- High efficiency (compared to external combustion engines)

- Moderate operating costs (compared to gas turbine engines)

- Easy refueling to maintain travel (compared to electric engines)

- These advantages have made internal combustion engines the predominant technology for over 100 years.

To better understand the operating principle, let’s delve into the basics of internal combustion engines.

The Operating Principle of Internal Combustion Engines

Simulation of Cannon Firing Process

First, a simple example of an internal combustion engine is a cannon. A cannon is a cylindrical tube sealed at one end. Gunpowder is packed into the barrel, and then a projectile (a pointed cylindrical shape) is placed to completely seal the gunpowder. When fired, a spark ignites the gunpowder. The rapidly generated gas creates a significant pressure increase in the barrel, propelling the projectile out of the cannon. The engine of a car is a mechanical system that harnesses this energy and converts it into rotational motion for the engine’s crankshaft.

Most modern cars use four-stroke engines (invented by Nicolaus Otto in 1867). The four strokes of an internal combustion engine are illustrated in Figure 1. They include:

- Intake Stroke (Intake valve open, exhaust valve closed).

- Compression Stroke (both valves closed).

- Combustion Stroke (Explosion – all valves remain closed).

- Exhaust Stroke (Intake valve closed, exhaust valve open).

We can see the detail moving up and down in the engine, which is the piston. The piston is connected to the crankshaft via a connecting rod. The entire process of the four strokes can be described as follows:

Figure 1: The Operating Principle of a Four-Stroke Engine

Legend: A: Intake valve, rocker arm, valve spring; B: Cylinder head; C: Intake manifold; D: Cylinder head; E: Cylinder block; G: Oil sump; H: Lubricating oil; I: Camshaft; Exhaust valve, rocker arm, valve spring; K: Spark plug; L: Exhaust manifold; M: Piston; N: Connecting rod; O: Gasket; P: Crankshaft.

1. The initial position of the piston is at the top, at which point the intake valve opens and the piston moves down to fill the cylinder with a mixture of air and fine gasoline particles (referred to simply as the air-fuel mixture) (part 1-yellow).

2. As the piston moves up to compress the air mixed with the fine gasoline particles, this compression enhances the efficiency of the combustion process (part 2-purple).

3. When the piston reaches the top dead center of its upward stroke, the spark plug ignites the air-fuel mixture. The burning gasoline creates an explosion within the cylinder, pushing the piston down (part 3-red).

4. When the piston reaches the bottom dead center, the exhaust valve opens, and as the piston moves up, it expels the gases from the cylinder through the exhaust pipe (part 4-blue).

Now, the engine is ready for the next cycle and continues to intake the air-fuel mixture. Note that the engine’s motion is the rotational motion of the crankshaft, while the piston’s motion is linear. To convert the linear motion of the piston into rotational motion, the crankshaft plays a crucial role. Now, let’s examine how the components of the engine are interconnected and work together.

The core of the engine is the cylinder, and the piston moves up and down within it. The engine described above is a single-cylinder engine. However, most modern car engines have not just one cylinder but can have 4, 6, 8, 12, or even 16 cylinders. In multi-cylinder engines, the cylinders can be arranged in one of the following ways: in a straight line (inline cylinders), in a V shape (V-shaped cylinders), horizontally opposed (flat engines), or in a star shape (commonly used in aircraft engines), as illustrated below.

Simulation of a 4-Cylinder Inline Engine

Simulation of a 6-Cylinder V Engine (V6)

Simulation of a 4-Cylinder Opposed Engine

Each arrangement has its own advantages and disadvantages regarding smooth operation, production costs, and structural design. The strengths and weaknesses of each type make them suitable for different types of vehicles. For example, V engines or inline engines with fewer cylinders are often used in cars, while inline engines with more cylinders are typically used in boats, and star-shaped engines are commonly used in aircraft…

Common Terms Used in Engines

First is “cylinder displacement.” The combustion chamber is the space where the compression and exhaust strokes occur. As the piston moves up and down, you can see the size of the combustion chamber changing. It can be at its maximum or minimum volume. The difference between the maximum and minimum volumes is called the cylinder displacement and is measured in liters or cc (cubic centimeters – 1000 cc equals 1 liter).

Here are some examples:

- A chainsaw needs an engine of about 40 cc

- A motorcycle requires an engine of about 500 cc or 750 cc

- A sports car needs a larger engine, around 5 liters.

- Most standard cars require engines ranging from 1.5 liters (1500 cc) to 4.0 liters (4000 cc)

If you have a 4-cylinder engine and each cylinder has a displacement of about half a liter, then your engine has a displacement of 2.0 liters. If each cylinder is half a liter but the engine has 6 cylinders arranged in a V shape, then your engine has a displacement of 3.0 liters, commonly referred to as a 3.0 V6 engine. Generally, the cylinder displacement gives you an idea about the engine’s power output. A cylinder with a displacement of 0.5 liters can hold twice the amount of air-fuel mixture as a cylinder with a displacement of 0.25 liters. Therefore, a 2.0-liter engine may provide half the power of a 4.0-liter engine. The cylinder displacement can be increased by increasing the number of cylinders or by enlarging the volume of the combustion chamber in each cylinder.

You have likely noticed that your vehicle’s engine is equipped with numerous auxiliary systems that help it operate efficiently. Most of these auxiliary systems are designed with various technologies. The more advanced the auxiliary system, the higher the engine’s performance, and vice versa. Let’s take a closer look at some of the auxiliary systems installed in modern engines.

Spark Plug

The spark plug is responsible for providing the ignition spark that ignites the air-fuel mixture, creating combustion within the engine. The spark plug must ignite at the right moment for optimal performance during the power stroke. (See the article on ignition systems in cars).

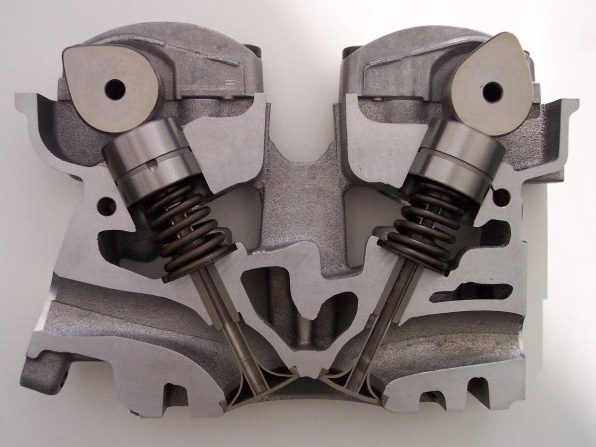

Valves (Intake and Exhaust)

Simulation of the valve timing mechanism

The intake and exhaust valves must open at the right time to allow the maximum amount of air into the cylinder and to exhaust the burnt gases efficiently. It is essential to note that both intake and exhaust valves are closed during the compression and power strokes to seal the combustion chamber.

Piston

The piston is cylindrical, made of metal, and moves up and down within the cylinder.

Piston Rings

Piston rings serve to seal the gap between the piston and the cylinder. They fulfill two main purposes:

- Prevent gas leakage during the compression and power strokes (this type of ring is also known as a compression ring).

- Prevent engine oil from entering the combustion chamber, as oil leakage would lead to significant oil consumption and reduced combustion efficiency (this type is known as an oil ring).

- In older vehicles, increased oil consumption often occurs due to worn oil rings, allowing oil to enter the combustion chamber and combust with the air-fuel mixture.

Connecting Rod

The connecting rod links the piston to the crankshaft of the engine. It moves in both a rotational and translational manner to convert the piston’s linear motion into the rotational motion of the crankshaft.

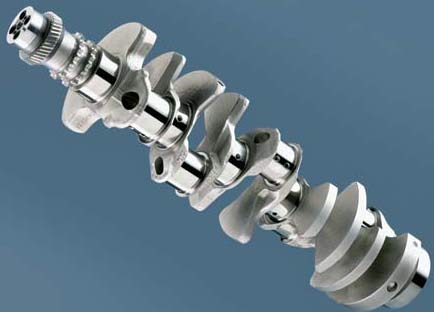

Crankshaft

Crankshaft

The crankshaft converts the linear motion of the piston into rotational motion, similar to the shaft in a screw mechanism.

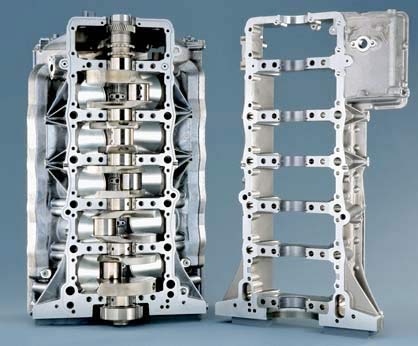

Crankcase

The crankcase surrounds the crankshaft and is designed to hold the lubricating oil.

Intake and Exhaust System

The intake and exhaust system consists of valves and a mechanical system that controls their opening and closing at the right times. The mechanism is called a camshaft. The camshaft has lobes that push the valves up and down.

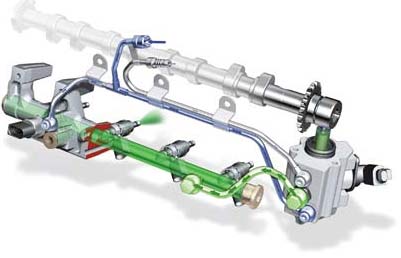

Components (camshaft, injectors, etc.) in the valve timing mechanism

Most modern engines use a camshaft mounted on the cylinder head, meaning the camshaft is directly above the valves, as seen in the illustration. The lobes on the camshaft directly actuate the valves or do so through a short linkage. Classic engines typically have a camshaft positioned below near the crankshaft, using pushrods to transfer the cam lobe’s lift to the valves via rocker arms.

Camshaft, valves, springs, lifters…

The camshaft is driven by a belt, chain, or gear that transmits the crankshaft’s motion to synchronize the opening and closing of the valves with the piston’s motion. In a four-stroke engine, the camshaft completes one full rotation for every two rotations of the crankshaft.

Camshaft drive chain and gear

Most high-performance engines today use four valves per cylinder (two intake and two exhaust) and therefore require two camshafts for a cylinder bank. This leads to the term “dual overhead cams (DOHC)”, indicating that two camshafts are placed over the cylinder head.

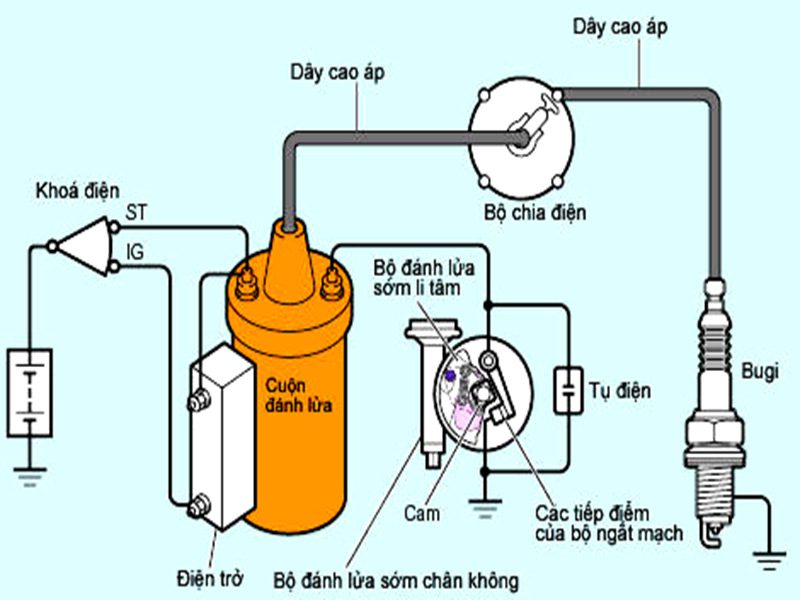

Ignition System

The ignition system generates a high-voltage electrical source and delivers it to the spark plug to create a spark that ignites the fuel. You can easily identify the ignition system by the distributor. The distributor has a high voltage lead connected to the center (also known as the primary high-voltage wire) and has 4, 6, or 8 high-voltage wires connected to the spark plugs (known as secondary high-voltage wires, the number of which depends on the number of cylinders in the engine). The distributor ensures that each cylinder receives a high-voltage pulse once per cycle at the right moment during the compression stroke for optimal combustion, allowing the engine to operate efficiently and smoothly.

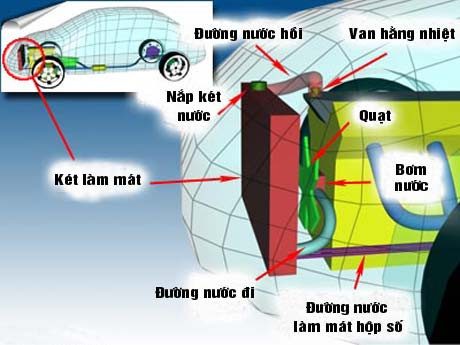

Cooling System

The cooling system in automobiles consists of a radiator and a water pump, along with pipes and temperature sensors. Water circulates through the engine and exits to the radiator for cooling. Some cars, including Volkswagen Beetles and various motorcycles or lawnmowers, use air cooling (these engines can be easily recognized by the cooling fins on each cylinder). Air cooling has the advantage of reducing engine weight but provides less effective cooling than water, leading to higher engine temperatures and reduced performance and lifespan.

Intake and Starting System

Most cars operate with a standard intake system (which draws air naturally due to the pressure difference between the outside air and the vacuum in the cylinder). For modern vehicles, to enhance engine performance, Turbocharged or Supercharged intake systems are employed to increase the amount of air entering the engine while improving the mixing of air and fuel, resulting in higher compression pressure, better combustion, and improved efficiency. The Turbocharged system utilizes a small turbine powered by exhaust gases to spin the compressor, while the Supercharged system uses the engine’s power directly to drive the compressor.

Turbine Blade Detail in Turbocharged System

Starting System consists of an electric motor and a starter solenoid. When you turn the ignition key, the electric motor turns the crankshaft a few times to initiate the compression and power strokes. The starter motor must overcome the following resistances:

- The total friction force of the engine

- The compression force of the engine cylinder (for any cylinder that is in the compression stage)

- The energy needed to open and close the valves

- All other auxiliary systems such as the cooling pump, oil pump, alternator, etc.

Since the power from the battery is only 12 V, and the electric motor must generate a significant amount of torque to overcome these resistances, the current used for the electric motor is quite high. To enhance the durability of the starting system, the load on the ignition switch must be reduced by using a solenoid to open and close the power supply to the starter motor. Thus, when you turn the ignition key to start the engine, you supply power to the solenoid to work, activating the power supply to the starter.

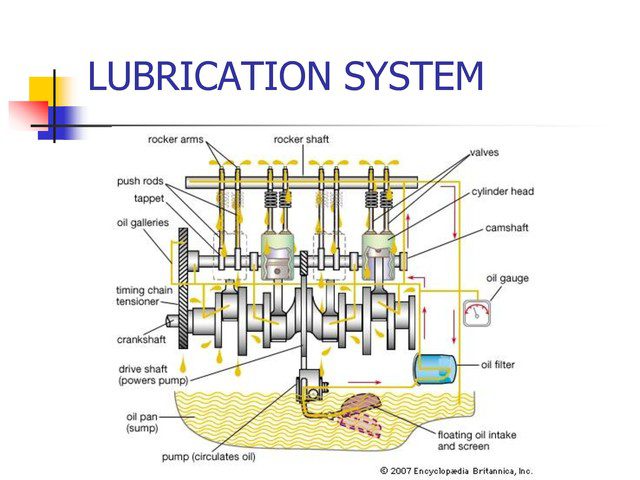

Lubrication System

Cylinder Block

The lubrication system serves to deliver lubricant oil to the surfaces of the engine’s moving parts, allowing them to move more easily. There are two main components that require lubrication: the pistons and the bearings or thrust bearings of the crankshaft and camshaft. In most engines, the lubricant oil is drawn from a reservoir, filtered, and then pumped under high pressure to the bearing surfaces and cylinder walls. Afterward, this oil flows back to the bottom of the oil pan to continue a new circulation cycle.

Fuel System

The fuel system pumps fuel from the tank and mixes it with air to create optimal combustion conditions within the cylinder. The fuel system is divided into three types: carburetion, indirect fuel injection, and direct fuel injection.

The carburetion system is responsible for mixing air with fuel as air is sucked into the cylinder.

In gasoline engines, an optimal amount of fuel is injected directly into the engine cylinder (direct fuel injection) or into the common intake manifold (port fuel injection).

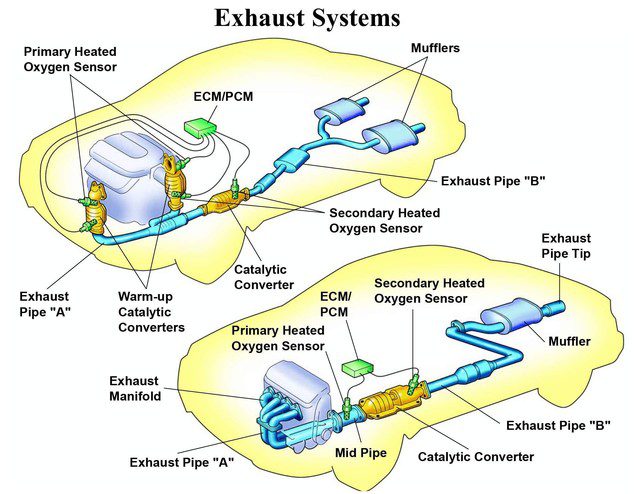

Exhaust System

The exhaust system includes the exhaust pipe and muffler. Without a muffler, you would hear the sound of thousands of explosions escaping from the exhaust pipe. The muffler reduces the engine’s noise level. The exhaust system also contains a catalytic converter to filter harmful substances from the exhaust before releasing them into the environment.

Waste Control System

The waste control system in modern cars consists of a catalytic converter, a sensing system, and actuators, along with a computer to monitor and adjust the operation of these components. For example, the catalytic converter uses catalysts and oxygen to completely combust any remaining fuel and chemicals in the exhaust pipe. An oxygen sensor placed in the exhaust flow informs the computer to adjust the appropriate amount of oxygen.

Electrical System

The electrical system comprises a power source (battery) and an alternator. The alternator, driven by a belt, generates electrical energy to recharge the battery. The 12-volt supply from the battery powers the entire electrical system, including the ignition system, radio, headlights, power windows, and central locking system through the vehicle’s wiring.

Modern Technologies in Today’s Car Engines

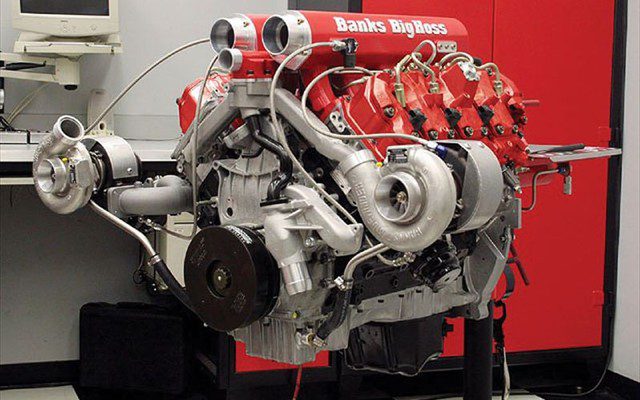

Turbocharging Technology

We often hear terms like turbocharged engine or twin turbocharger. So, what is turbocharging technology in engines? Engines need three things to operate: fuel, air, and ignition. Compressing more air into the cylinder creates more power for the engine, typically using a component known as a turbocharger or supercharger. Their job is to compress air into the combustion chamber at high pressure, creating a higher compression ratio. Similar to overclocking in computers, turbocharging in engines helps vehicles achieve greater power.

Overhead Camshaft

DOHC (Dual Overhead Camshaft) refers to the number of camshafts per cylinder in the engine. The camshaft controls the flow of fuel and air entering the combustion chamber. An overhead camshaft allows for more intake and exhaust valves in the engine, meaning more fuel and air can enter the combustion chamber. This also enhances exhaust efficiency, adding power to the engine.

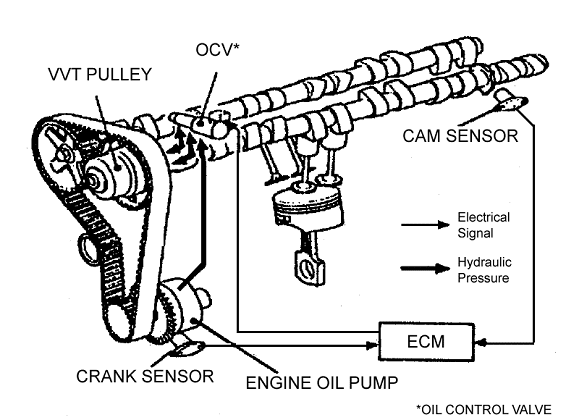

Variable Valve Timing Control

The computer calculates when to add more air and fuel to enable better acceleration or decrease the intake when the engine operates at lower speeds. Toyota calls this technology VVT-i (Variable Valve Timing with Intelligence), Honda refers to it as VTEC, and BMW has Valvetronic technology.

Engine Control Computer

Modern cars typically have a component controlling their operations called the ECU (Engine Control Unit). This component tightly regulates the ignition timing of the spark plugs, the amount of air and fuel intake…

Additionally, there is another computer that manages the electrical system, airbags, temperature, and the anti-lock braking system (ABS).

Next-Generation Diesel Engines

Modern diesel engines are much stronger, cleaner, and more fuel-efficient than those of the past. These machines use low-sulfur diesel fuel to reduce harmful emissions. Diesel engines from manufacturers like Volkswagen, Mercedes, and BMW utilize turbocharging or direct fuel injection for high efficiency. This is also a significant factor for customers to consider when purchasing a vehicle.

Hybrid Engines

The rising fuel prices and significant environmental concerns have led to substantial changes, with hybrid engines being the most notable. These engines combine modern electric motors with traditional internal combustion engines to reduce fuel consumption and emit fewer pollutants. The Toyota Prius is the best-selling hybrid car in the U.S. Its 1.8L combustion engine works alongside an electric motor generating a total output of 134 horsepower. At low speeds, the electric motor operates, and the vehicle uses no fuel. At high speeds, there is a combination of traditional and modern propulsion. Fuel consumption is around 4.7 liters per 100 km in mixed conditions.