This type of train lacks wings and any kind of wheels, nor does it operate on magnetic levitation. Instead, it runs high above the ground, several meters in the air. This represents a revolution in the design, manufacture, and operation of trains.

It is recalled that during the early industrial revolution in England, coal miners had to transport coal through tunnels using wooden carts with wooden wheels. The work was incredibly laborious. Then, someone came up with the idea of laying planks to create tracks for the wheels—reducing friction and making the job somewhat easier. Gradually, planks were replaced by iron rails, and wooden wheels were replaced with iron ones. Single tracks evolved into double tracks, and the one-wheeled carts were replaced by four-wheeled iron wagons. This is essentially how railways came into existence.

For centuries, people have become accustomed to the sight of iron rails fixed to the ground with wheels attached to train cars, without anyone considering the reverse: rails attached to the train cars while the wheels remain… on the ground. Recently, a group of American engineers thought of this “upside-down” concept, and the results have been spectacular.

The term “Tubular Rail” for this project does not fully capture the essence of the matter, as the project discusses a type of rail transport that doesn’t require traditional tracks at all.

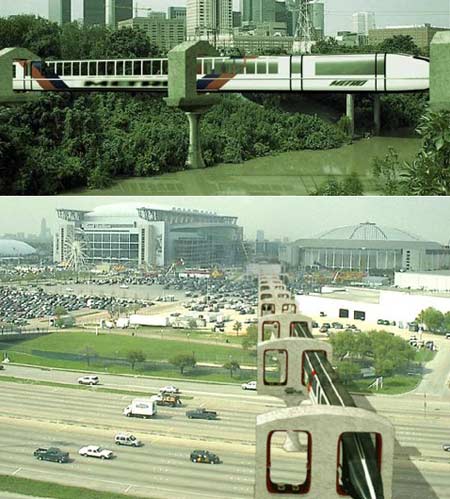

Imagine a very long train car speeding along a track elevated 10-15 meters above the ground, similar to those found in amusement parks. If we eliminate the tracks, we have what the Tubular Rail authors propose. But how does the train car float in the air? Not quite. The bottom, top, and two sides of the car rest firmly on a concrete frame positioned atop tall columns. The train car must be made from super-durable materials and is twice the length of the distance between two adjacent concrete frames. The train car does not have wheels, as they are embedded within the concrete frame. The wheels are powered by electric motors, pressing against the sides of the train car and “pushing” it forward. A remote control device on the train car allows the operator to adjust the power of the electric motors to control the speed of the train as desired. This is incredibly convenient.

The advantages of this transportation method include significantly lower construction costs, much less than building traditional ground railways, as it occupies almost no ground space and does not require a raised foundation like conventional railways. This means it does not disrupt the landscape when traveling through cities or residential areas. The construction time is also many times faster compared to traditional ground rail construction. Each supporting column for the concrete frame occupies a land area equivalent to that of an average tree and resembles a tree stump. The overhead concrete frame appears as a charming little structure, not detracting from the city’s aesthetics.

From a technical standpoint, if one or two of the wheels in a concrete frame malfunction, it has minimal impact on the movement of the train car. Additionally, since the train car does not need to carry extra wheels, the useful load capacity can be increased. The energy consumption of this transportation method is also significantly lower compared to conventional trains. Before widespread application, the project authors are actively seeking investment to build short routes in Texas to facilitate travel from major cities to satellite towns.