Engineers at the University of Pittsburgh (Pitt) have developed a versatile and ultra-lightweight smart concrete that can adjust its properties for various construction projects and generate electricity on its own.

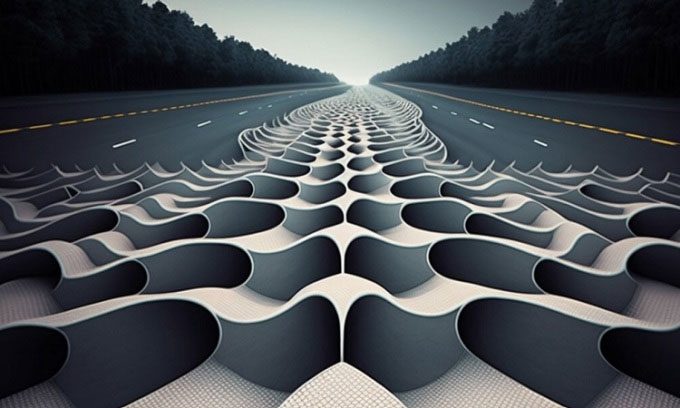

Simulation of smart concrete material used on highways. (Photo: Amir Alavi).

This new supermaterial consists of a network of auxetic polymers reinforced within a conductive cement matrix. The conductive cement is enhanced with graphite powder, forming electrodes. A mechanical stimulus can lead to electrification between the layers. The concrete created by Amir Alavi’s research team, an assistant professor of civil and environmental engineering at Pitt, does not produce enough energy to feed into the power grid but can be used to monitor damage within concrete structures, such as in the event of an earthquake. They published their research findings in the journal Advanced Materials, as reported by New Atlas on March 22.

“The widespread use of concrete in infrastructure projects requires the development of a new generation of concrete materials that are economical and environmentally sustainable while still providing advanced functionalities. We are confident that we can achieve all these goals by incorporating supermaterials into building material development,” Alavi stated.

The supermaterial itself can be customized to meet construction needs, altering flexibility, shape, and brittleness. In tests, it can compress up to 15% while maintaining the integrity of the structure.

“This project creates the first composite supermaterial concrete with ultra-high compression and electricity generation capabilities. Such ultra-light and mechanically adjustable concrete systems could pave the way for diverse applications like shock-absorbing materials at airports, helping to slow down aircraft on runways or seismic isolation systems,” Alavi mentioned.

The research team hopes that this new versatile concrete can be widely used in infrastructure. This smart material could even provide power for chips embedded in highways to support autonomous vehicles. However, in the near future, scientists will need to conduct large-scale testing and understand how to shield the material from environmental pressures such as humidity, wet weather, and temperature fluctuations.