Concrete with microcapsules containing water treatment powder can prevent corrosion in drainage systems, significantly reducing costs.

The corrosion of drainage pipes occurs when the pipe material comes into contact with sulfuric acid. The aging material corrodes, leading to cracks and breaks in the pipes. In recent years, experts have developed robots to inspect sewage pipes, reaching areas that are unsafe for humans. However, this also means that the robots must go to places where current wireless communication systems have not yet penetrated.

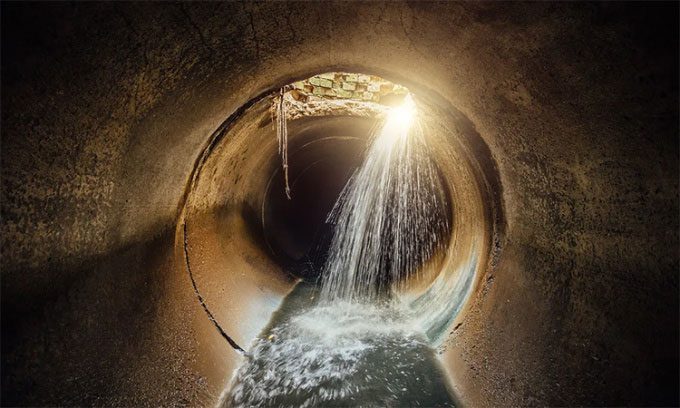

Maintaining drainage systems can be very expensive. (Photo: Vladimir Zapletin/iStock)

Professor Yan Zhuge, an engineering expert at the University of South Australia, is testing a new solution to this problem, as reported by Interesting Engineering on December 17. The solution does not require human or robot intervention but utilizes self-healing concrete.

This is the first project of its kind in the world and will be highly beneficial if successful. The project could prevent 17,000 kilometers of drainage pipes in Australia from cracking in the future without human intervention, helping to save $1.4 billion in annual maintenance costs.

Every year, experts spend significant amounts of money addressing the issues caused by deformed sewage pipes due to internal pressure, temperature changes, and acid corrosion. Self-healing concrete, with microcapsules filled with water treatment powder, can solve this problem.

“The water treatment powder has the potential to reduce microbial corrosion in concrete drains as it acts as a healing agent against acid corrosion and seals cracks,” Zhuge said.

Specifically, the research team will develop microcapsules with pH-sensitive shells and a core made of healing agents from alum – a byproduct of wastewater treatment plants – and calcium hydroxide powder. This mixture will help combat microbial corrosion. The capsules will then be added to the concrete during the final mixing stage to protect the concrete from cracking. When the pH changes, the capsules will release the healing agents.

“This new technology not only extends the lifespan of concrete structures, saving over a billion dollars for the Australian economy, but also promotes a circular economy by reusing alum powder that is often discarded in landfills,” Zhuge stated.