The Impossible Metals machine is deployed to a depth of 25 meters, using its arms to collect metals from the seabed without harming the ecosystem.

Impossible Metals, a company based in the United States and Canada, has developed a machine to collect metals from the ocean floor without disrupting the ecosystem, Design Boom reported on December 12.

(Video: Impossible Metals)

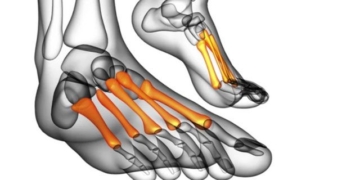

As the world shifts towards environmentally friendly energy solutions, the demand for reusable batteries is on the rise. These batteries typically require nickel and cobalt. With the increasing scarcity of these metals on land, humans are beginning to search for them on the ocean floor. There, they can appear as polymetallic nodules, concentrated in large clusters. Polymetallic nodules, or manganese nodules, are solid blocks found on the seabed, containing iron oxyhydroxides and manganese oxides, along with metals such as nickel, cobalt, copper, titanium, and rare earth elements.

Current prototypes for mining these polymetallic nodules often rely on traditional dredging technology. However, Impossible Metals’ solution helps limit biodiversity loss while providing a more economical approach.

Simulation of the metal collection machine operating on the ocean floor.

The prototype machine from Impossible Metals is named Eureka 1, which is deployed from a mother ship to a depth of 25 meters. It immediately activates its cameras and arms on the underside. The machine uses a sensor system to navigate and identify the polymetallic nodules. While hovering above the seabed, its robotic arms collect essential metals below, avoiding rocks where marine life may reside and preserving the underwater habitat.

Eureka 1 is also equipped with a unique buoyancy propulsion system that allows it to ascend and return to the mother ship, carrying the collected materials. In preliminary tests conducted in November, Eureka 1 remained connected to a communication cable to switch between manual and automatic control modes. However, the machine is expected to become fully automated in the future.