China Completes Core Component of the International Thermonuclear Experimental Reactor (ITER), the World’s Largest “Artificial Sun”.

The production process for the full-scale prototype of the Enhanced Heat Flux First Wall (EHE FW) for the ITER project has been completed with significantly better performance indicators than the design requirements, paving the way for mass production. This marks a new breakthrough for China in the scientific research of core technology for EHE FW, reported Xinhua on November 22.

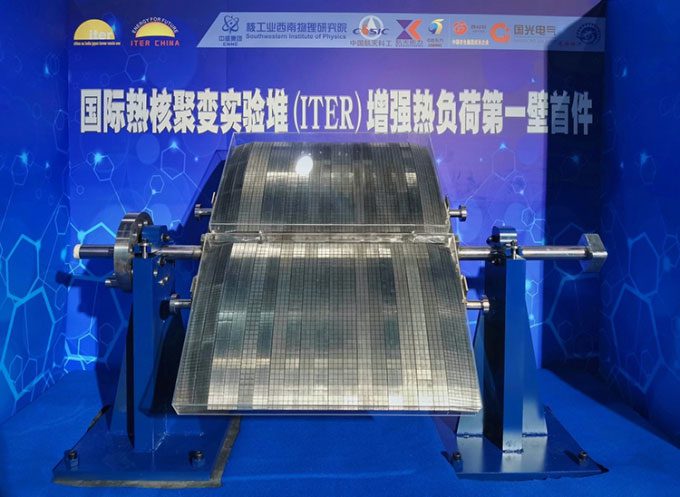

The Enhanced Heat Flux First Wall will be in direct contact with plasma heated to 100 million degrees Celsius, making it one of the most critical components of the reactor. The full-scale prototype of the EHE FW, measuring 1.5 meters in length and 1 meter in width, was developed by the Southwest Institute of Physics under the China National Nuclear Corporation.

Close-up of the EHE FW prototype. (Photo: China Science)

The International Thermonuclear Experimental Reactor is often referred to as the “Artificial Sun” because it generates clean, carbon-free energy in a manner similar to how the sun emits light and heat through nuclear fusion. This reaction is achieved by mixing two isotopes of hydrogen heated to approximately 150 million degrees Celsius, which is about ten times hotter than the core of the sun.

“We have a machine at the center of the reactor, which, to put it simply, is a scaled-down version of the sun. It generates energy, and we will use that energy to produce electricity,” said Robert Arnoux, a spokesperson for ITER, in an interview with AFP.

ITER is one of the largest and most significant international scientific research projects in the world, jointly funded and operated by seven members: China, the European Union, India, Japan, Russia, South Korea, and the United States.

China signed an agreement to initiate the ITER project with the other six parties in 2006 and has been responsible for about 9% of the work in this nuclear fusion experiment. According to Global Times, their EHE FW production technology has become the first technology to receive international certification.