American scientists have successfully developed a flexible plastic material inspired by living organisms, with many promising applications.

In living organisms, structures such as muscles and skin often seamlessly combine various properties like strength and flexibility. Scientists have long sought to mimic this using synthetic materials, but these often fail, separate, or tear at the interface of different properties.

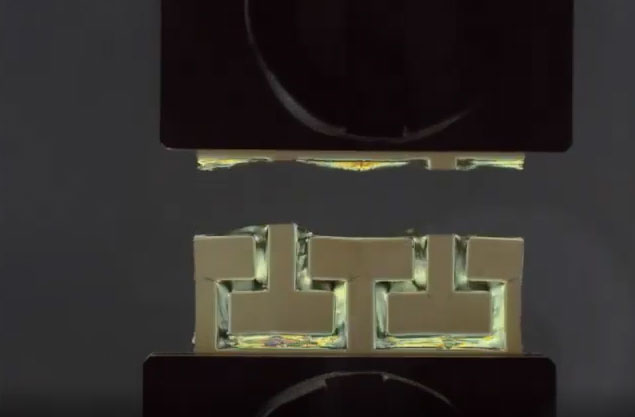

Stretch tests of the smart plastic, with darker sections hardened while lighter areas remained soft and elastic. (Video: UT Austin)

“Typically, when you compress materials together, especially if they have very different mechanical properties, they tend to want to separate,” said Zachariah Page, an associate professor of chemistry at the University of Texas at Austin (UT Austin).

In a new study published in the journal Science, Page and his colleagues discovered a way to control the structure of a type of plastic material by using light and catalysts to alter properties such as hardness and elasticity. Essentially, it resembles many forms of life that can be soft and elastic in some areas but hard in others, Interesting Engineering reported on October 24.

“This is the first material of its kind. The ability to control its crystallization and physical properties has potential applications in wearable electronics or actuators in soft robotics,” Page added.

This material is ten times harder than natural rubber when exposed to light.

To create the smart plastic, the research team used monomers, small molecules that bond with similar substances to form “building blocks” for larger structures known as polymers. The polymers in this case are similar to those found in the most common types of plastics.

It took about ten trials for Page and his colleagues to find a catalyst that, when added to the monomer and illuminated, produced a semi-crystalline polymer similar to that found in existing synthetic rubber. This material is ten times harder than natural rubber in areas exposed to light but remains soft and elastic in areas without light.

The experiments can be conducted at room temperature, with readily available monomers and catalysts, while the light source is a simple green LED. Additionally, the reaction occurs in less than an hour and does not release harmful substances, making the process quick, cost-effective, energy-efficient, and environmentally friendly.

In the next phase, the research team will focus on testing this material on various subjects to assess its potential applications. They envision a flexible material that could be used to anchor electronic components in devices such as medical equipment or wearable technology. These flexible and strong materials could also enhance the movement and durability of robots.