Concrete is an essential building material; however, outside of Earth’s environment, the production of this material is incredibly challenging and vastly different from what we do here on Earth.

Many of us may already know that in the near future, if humans live on Mars, the Moon, or any other distant planets, they will have to lead a life primarily based on self-sufficiency.

This means that they will need the necessary means to produce food, fuel, and even air on-site. However, to achieve this, they must first secure a safe shelter, and building a permanent settlement far from Earth may be the most challenging task of all.

According to current calculations, the cost to send 1 kg of cargo into space using SpaceX’s Falcon rocket, which is frequently used to supply the International Space Station, is about $2,700 (approximately 632 million VND).

However, the cost to send 1 kg of material to Mars is significantly higher—Mars Curiosity cost approximately $2.5 billion to land an 889 kg rover on Mars, translating to about $2.78 million per kg.

Even if you have a lot of money, the maximum payload for each journey is limited, which means we cannot transport any type of building materials to Mars or even the Moon.

We cannot transport any building materials to Mars or the Moon.

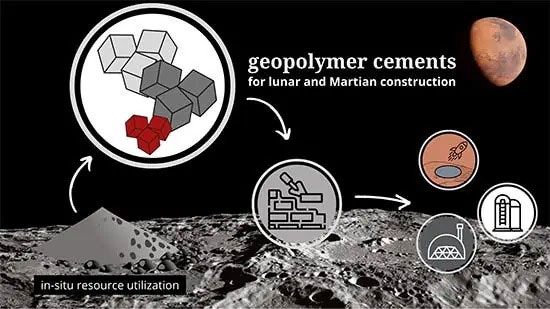

Nevertheless, geologists and chemists at the University of Delaware have a promising idea: to utilize natural resources available at the destination to produce building materials.

This may sound like an obvious approach, but transforming substances on the surface of Mars into reliable and effective building materials is not straightforward according to previous research.

A key requirement for any extraterrestrial settlement is durability and strength. At this point, concrete is an excellent choice, but the formula for producing concrete requires cement—a material that cannot be transported into space.

Geopolymers are inorganic polymers.

To address this issue, researchers led by Professor Norman Wagner at the University of Delaware have turned to the study of geopolymer chemistry. Geopolymers are inorganic polymers made up of aluminosilicate minerals that form solid, ceramic-like materials at near-ambient temperatures. On Earth, they are commonly found in clay almost everywhere.

When these geopolymers are mixed with alkali solvents, such as sodium silicate, the clay dissolves, releasing aluminum and silicon to react with other substances and form new materials—including cement.

The soil on Mars or the Moon also contains these common clays, but achieving this process outside of Earth is “not straightforward,” Wagner states. “You can’t just say that having clay means we can successfully carry out this process. However, there are still precision measures and chemical factors that you must carefully calculate for the extraterrestrial environment.”

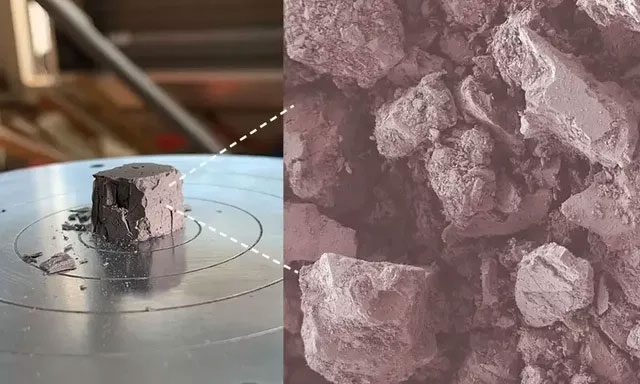

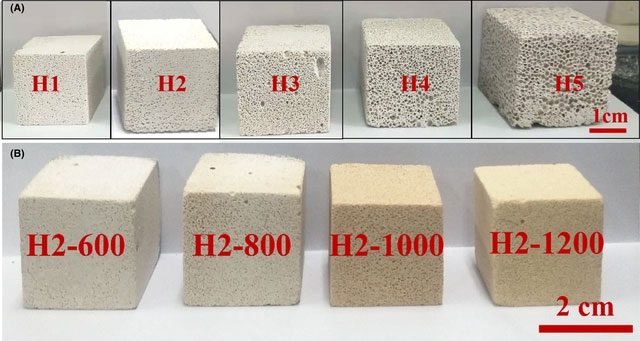

For this new study, the scientists mixed simulated Martian and lunar soil with sodium silicate, then cast the liquid mixture into cubic molds. After a week, the materials from each mold were removed, measured, and weighed before being tested structurally to see how much load they could withstand. The materials also had to endure various environmental factors they would encounter in space, including vacuum conditions and extreme high and low temperatures.

Wagner said: “When a rocket launches, there is a significant amount of weight pushing down on the launch pad, so the compressive strength of the material becomes an important measure. At least on Earth, we have been able to create materials in small cubic forms that have the compressive strength necessary to perform this task.”

Tests showed that geopolymer cement had poor compressive strength when formed in vacuum conditions.

The researchers reported successfully converting a simulated regolith material from Mars and three simulated regolith materials from the Moon into geopolymer binders. The tests indicated that geopolymer cement exhibited poor compressive strength when formed in vacuum conditions. Meanwhile, at temperatures below -80 degrees Celsius, the geopolymer did not undergo any chemical reactions. This indicates that astronauts will need to cast these materials in a pressurized environment, and the geopolymer will need to be heated.

Instead of packing bags of cement to send to Mars, with these research results, astronauts would only need to bring the solvent with them. The amount they need to build a moderately sized settlement may fit well within the payload capacity of a rocket launching to Mars.

Geopolymers require less water than traditional cement to produce because water is not absorbed by the reaction itself. This means it can be recovered and reused. Researchers at the University of Delaware are busy constructing 3D-printed houses using geopolymer cement, which they plan to activate using microwave technology.