Cutting down trees and processing wood is not the most effective or environmentally friendly way to make furniture or construct buildings. Currently, wood can be a renewable resource, but humans are using it much faster than it can be replenished. Deforestation is having a profound impact on wildlife and exacerbating the effects of climate change. As human demand for wood products is unlikely to change, what needs to change are the methods of producing them.

In recent years, researchers have turned to growing wood in the laboratory. Of course, these are not trees, but rather cultivated wood. This process is not unlike growing animal cells for meat in a lab, instead of raising live animals and slaughtering them.

When wood can be 3D printed, humans will no longer need to cut down trees as much as they do today.

Now, a team of scientists from MIT has demonstrated a new technique that can “grow” a wood-like plant material in the laboratory, allowing for easy adjustments to properties such as weight and strength as needed.

“The idea is that you can grow these plant materials in the exact shape you need, so you won’t have to perform any cutting production steps, which reduces energy consumption and waste,” said Ashley Beckwith, the lead author of the study. “There is a lot of potential to scale this up and develop three-dimensional structures.”

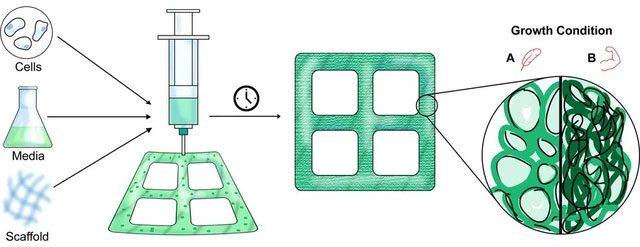

Initially, the research team isolated cells from the leaves of a plant known as Zinnia elegans. These cells were then cultured in a liquid medium for two days before being transferred to a thicker gel medium. This gel contains nutrients and two different types of plant hormones, with their levels adjustable to change the physical and mechanical properties of the material.

Next, the team 3D printed this cell-containing gel into a specific shape, similar to how one would 3D print an object from plastic. After three months of incubation in the dark, the material lost moisture, resulting in a custom object made from wood-like plant material. For instance, in one experiment, the research team shaped the material into a model of a tree.

An illustration showing how plant cells can be cultured and 3D printed into custom shapes, with different properties based on varying hormone levels.

The research team experimented with different levels of hormones and found that lower levels resulted in a material with lower density and open, round structures. In contrast, higher levels made them smaller, with denser and harder structures, thanks to increased lignin growth (a natural polymer that is the second most abundant in the world after cellulose). This difference can be used to create products with softer and lighter properties or stronger and harder ones, as needed.

Ultimately, the goal of the research is to develop the technology to the point where wood-like objects can essentially be 3D printed, rather than cut, shaped, and assembled from large pieces of wood obtained from tree cutting. This process could begin with small wooden objects or decorations before moving on to furniture or panels for construction.

The research team stated that the next step is to find ways to apply this method to other types of plants. Zinnia is not a timber tree, so adjusting the process to make it work with something like pine wood could be a significant breakthrough.

The study has been published in the journal Materials Today.