The shiny, silver-white metal with a hint of gold has accompanied humanity for over 5,500 years. In the global nickel production, 68% is used in the manufacture of stainless steel, 10% for producing nickel-based and copper-based alloys, 9% is used in stainless plating, 7% for steel alloys, and 3% in foundries.

The remaining amount (only about 3%) is used for various other purposes, including the nascent electric vehicle industry, which relies heavily on batteries containing nickel.

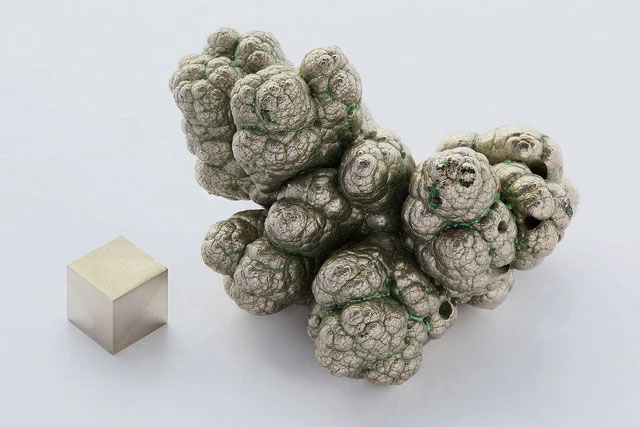

Image of a block of nickel.

On the other hand, we have a millennia-old story about the history of nickel. When the Germans in the Middle Ages discovered a golden-looking metal resembling copper ore in the Erzgebirge (Ore Mountains), they attempted to extract copper but were unsuccessful. The blacksmith blamed Nickel, a mischievous character in German folklore, and referred to the strange metal as “kufernickel” (with “kufer” meaning “copper” in German).

In 1751, Baron Axel Fredrik Cronstedt, a distinguished chemist and mineralogist from Sweden, tried to extract copper from a block of kufernickel taken from the mine in the village of Los. Contrary to expectations, the smelting process yielded a white metal unknown to science.

The Baron named the metal “Nickel”, inspired by the old German tale. Today, the village of Los, the starting point of the historical ore sample containing “nickel”, has become a famous tourist destination in Sweden.

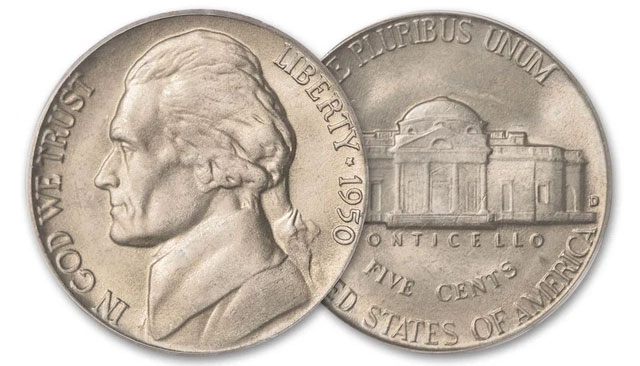

In the United States, a 5-cent coin contains 1.1 grams of nickel and 3.75 grams of copper. As of April 2007, the total value of these two metals in a 5-cent coin reached… 9 cents. This significant discrepancy led the U.S. Mint to declare a ban on citizens “melting” coins for their metal; violators could face fines of up to $10,000 and a maximum prison sentence of 5 years.

U.S. 5-cent coin containing a lot of nickel.

Commonly used metal with a challenging extraction process

Alongside iron, cobalt, and the rare earth element gadolinium, nickel is one of the four elements that exhibit ferromagnetism when placed near room temperature. This means nickel is one of the elements used in the production of magnets and is also strongly attracted by magnetic devices. Nickel is an essential metal in battery production, the technology that drives the success of electric vehicles. However, only about 3% of nickel production supports this fledgling industry.

Besides its magnetic properties applied in various technological aspects, nickel is also widely used in metallurgy and countless other consumer goods.

Electric vehicle batteries, or rechargeable batteries in general, require nickel.

Thanks to its corrosion resistance, blacksmiths from ancient times used nickel for plating items. In modern industry, nickel is an essential “functional food” that helps create strong, durable alloys and enhances toughness. The list of elements that can pair with nickel to form strong alloys includes copper, chromium, lead, cobalt, silver, and gold.

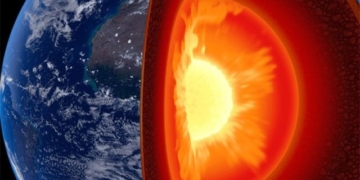

Rare and widely used, but only a small amount of nickel exists in its pure form. Nickel constitutes a very small fraction of the Earth’s crust and is also found in the cores of nickel-iron meteorites that remain suspended in space, never having come into contact with atmospheric oxygen.

On Earth, nickel commonly appears with sulfur and iron in the sulfide pentlandite, alongside sulfur in millerite, paired with arsenic in the mineral nickeline, and exists with both arsenic and sulfur in the natural mineral nickel galena. The Earth’s crust contains a total of 52 minerals with the nickel element.

One cubic centimeter of nickel refined through electrolytic technology next to a block of crystallized nickel salt.

However, the mining industry primarily seeks nickel in two types of ores:

The first is laterite – a term referring to a type of soil rich in iron and aluminum typically formed in hot, humid tropical regions. The main components in laterite include nickel-rich iron ore limonite, along with garnierite – a nickel-containing hydrated silicate rich in nickel.

The second, the mining industry also utilizes sulfide ores containing pentlandite, which is rich in iron and nickel.

According to surveys, nickel accounts for 1% (possibly more) of the total land-based resource reserves, equivalent to at least 130 million tons. Of this, about 60% of nickel is found in laterite, while the remaining 40% is stored in sulfide deposits.

The high importance increases the risk of a dependent supply

It is estimated that the largest nickel reserves are located in Indonesia and Australia, accounting for 43.6% of the world’s total nickel reserves. Accordingly, Indonesia is the leading country in annual nickel extraction.

Based on survey data from 2020, the mining industry extracts 2.5 million tons of nickel from the earth each year, with Indonesia contributing 760,000 tons, the Philippines 320,000 tons, Russia 280,000 tons, and Australia 170,000 tons. However, the world’s largest producer of refined nickel is Norilsk Nickel, a country with the third-highest nickel extraction output globally.

Norilsk Nickel’s production facility.

Headquartered in Moscow, the Russian company is under significant pressure from escalating political tensions. Consequently, the global nickel supply is impacted, directly affecting the thriving electric vehicle industry. However, this also presents an opportunity for countries with large nickel reserves to recognize their immense potential.

According to data from the Government Information Channel of Vietnam, the total nickel reserves and resources in Vietnam are estimated at approximately 3.6 million tons, primarily concentrated in Thanh Hoa province with over 3 million tons, Son La with 420,523 tons, and Cao Bang with reserves of 133,677 tons. During this period of significant change, the potential from Vietnam’s nickel mines could help us assert our position in the global supply chain while enabling Vietnam to achieve self-sufficiency in essential battery technology for the technological era.

Conclusion

Humanity will never have to worry about a lack of nickel. Whether we look high up or deep down, we see the presence of this precious metal.

Nickel reserves account for only 1% of total land-based resource reserves, but beneath the sea, at depths of 3.5 to 6 km below sea level, a rich nickel deposit awaits the right technological advancements. Located in the Clipperton Fracture Zone off the Pacific Ocean, small polymetallic nodules rich in rare earth elements and many valuable elements are still waiting for us to exploit. It is estimated that the nickel reserves in these polymetallic nodules reach up to 1.7%.

And when we fully harness the available energy on Earth, humanity may look to space to seek new horizons for conquest. With the ability to mine resources from asteroids, we could soon become the dominant species in the Solar System.

For now, let’s just dream about it. To achieve a future that still resides within the vast realm of “science fiction,” humanity needs to build on the most solid foundations. And a foundation made from many precious minerals, such as nickel, is indeed a sturdy platform.