Rice University Successfully Recovers Rare Earth Elements from Waste with Important Properties for Electronics and Green Technology.

An interesting fact: Rare Earth Elements (REE) are actually not rare. However, all REE are typically not concentrated and are very difficult to extract from mined minerals.

This is truly problematic because REE are essential components in over 200 products across various applications, particularly in high-tech consumer products such as mobile phones, computer hard drives, electric vehicles, hybrid cars, flat screens, and TVs.

A few years ago, scientists from Rice University in the United States developed the Flash Joule Heating (FJH) technique to create graphene material from any solid carbon-based waste source. In a recent study, they successfully applied this method to three waste sources – fly ash, bauxite residue, and electronic waste – to recover rare earth metals.

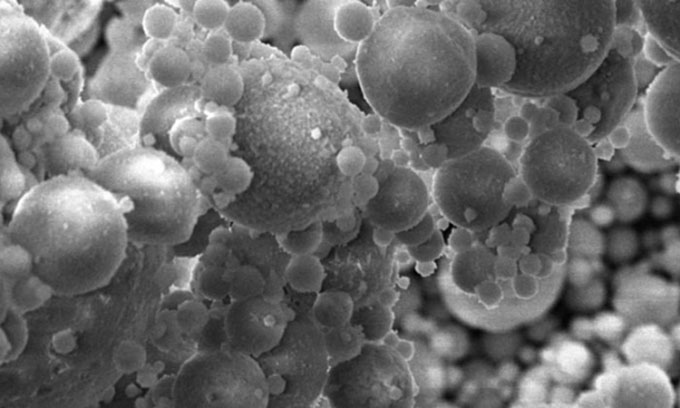

Tiny glass beads found in fly ash containing REE. (Photo: Rice University)

The United States previously mined rare earth elements but also extracted a significant amount of radioactive elements. They were not permitted to reprocess them due to the high costs and environmental repercussions, leading to a complete halt in mining operations. Today, much of what was mined is either piled up or buried in fly ash, a byproduct of coal-fired power plants.

“We have mountains of fly ash. The residue from burned coal is silica, aluminum, iron, and calcium that forms glass around trace elements, making them very difficult to extract,” said chemist James Tour, a co-author of the study. “Bauxite residue, sometimes referred to as red mud, is a toxic byproduct of aluminum production, while electronic waste comes from outdated devices such as computers and smartphones.”

The industrial extraction process from these waste sources often involves leaching with strong acids, which is both time-consuming and harmful to the environment. In Rice University’s new method, researchers heated fly ash and other materials combined with carbon black to increase conductivity to about 3,000 degrees Celsius in one second. This allows them to convert waste into highly activated REE, possessing magnetic and electronic properties crucial for electronics and green technology.

Tour noted that the FJH treatment of fly ash helps break down the glass surrounding the elements and transforms REE phosphates into much more soluble metal oxides. The generalizability of the process is what makes it promising, as millions of tons of bauxite residue and electronic waste are generated each year.

The research has been published in the journal Science Advances.