Plastic plays a crucial role in modern life as well as in the production lines of essential goods. However, the high costs of recycling plastic and its potential to cause severe pollution have led to a decline in its favor, even though it remains widely used.

A new type of plastic made from DNA and vegetable oil could change everything. The production process requires less energy, and the final product is easier to biodegrade or recycle.

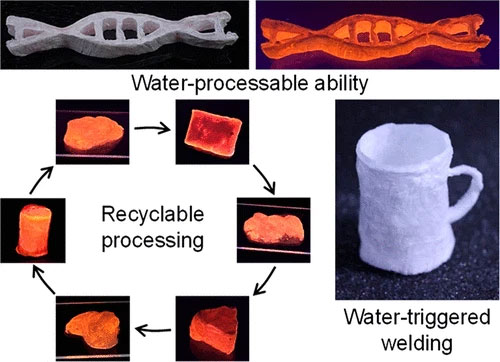

A cup made from the new plastic.

Traditional plastics are harmful to the environment because they are made from crude oil-based chemicals and are non-recyclable. The production process requires a large amount of energy and toxic chemicals, and the decomposition process can take hundreds of years. Plastic recycling efforts are still inefficient, contributing to pollution of both land and water.

New bioplastics synthesized from plants are becoming more common due to their good biodegradability. However, the production of plastics from seaweed or corn starch requires significant energy.

To address these challenges, a research team at Tianjin University, led by Professor Dayong Yang, has developed an advanced type of plastic to tackle these issues. By attaching short DNA strands to a chemical extracted from vegetable oil, the team created a soft and flexible material. Notably, the DNA used is derived from salmon sperm.

With the new plastic, the team has experimented with creating various shaped objects.

Mr. Yang and his colleagues have tested pouring the new material into molds and placing it in a cold environment to remove moisture, solidifying the mixture into plastic. Using this new plastic, the team has successfully created a variety of shaped objects, achieving promising results.

When placed in water, objects made from the new plastic revert to a malleable state and can be remolded again. It appears that the recycling process for this plastic is straightforward.

“What I like about this type of plastic is that you can decompose it and start over,” remarked researcher Damian Laird from the University of Australia. “Most studies focus on developing biodegradable plastics, but if we want to create a closed-loop economy, we should also recycle them to avoid material waste.”