Scientists and engineers at the University of Cambridge have developed a new nano material for air filtration that can吸引 and eliminate various types of viruses, including close relatives of nCoV.

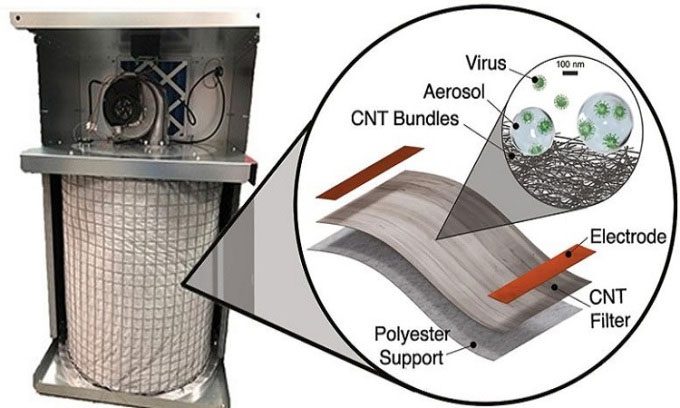

The interdisciplinary research team from the Boies Group, the Department of Engineering, the Department of Materials Science, and the Department of Pathology at the University of Cambridge tested a prototype filtration system equipped with an electrically conductive membrane made from ultra-thin carbon nanotubes. This new type of filter allows for the filtration of viruses and immediate sterilization through thermal bursts by continuously heating above 100 degrees Celsius, thereby inactivating viruses, including betacoronaviruses, within seconds.

Air filter design by researchers at the University of Cambridge. (Photo: University of Cambridge)

The researchers stated that the multifunctional filter is particularly useful in preventing the airborne transmission of viruses in confined environments such as ambulances, hospitals, recreational areas, and educational centers. The system can operate independently or be integrated with heating, ventilation, and air conditioning (HVAC) systems. The research team published their experimental results with infectious viruses along with theoretical models in the journal Carbon.

According to the study, the new filtration system can be mass-produced, possessing efficient filtration capabilities and airflow comparable to commercial HEPA filters (high-efficiency particulate air filters). This design captures respiratory droplets containing high concentrations of viruses, such as the coronavirus, which can be released when coughing, speaking, or breathing, remaining airborne for hours and traveling tens of meters in confined spaces. These respiratory droplets contribute to high infection rates in crowded and enclosed areas.

Produced through a unique process invented by the university, the carbon nanotube material has significant potential for commercial applications. “Based on the insights gained from the project, some prototypes we developed can filter 99% of the air in a small room or ambulance within 10 to 20 minutes. To meet market demand, we are upgrading the process to achieve commercial scale, producing over 100,000 square meters of membrane material each year,” said Liron Issman, a PhD candidate.