Scientists Create Sulfur-Selenium Coating That Protects Steel in Seawater and Self-Heals When Cut or Punctured

A team of experts at Rice University in the United States has developed a new compound with unique properties that effectively protects steel from corrosion, as reported by New Atlas on October 19. This compound can be used as a rust-resistant coating for steel bars submerged in water, while also being highly flexible, easy to bend, and capable of self-repairing when damaged.

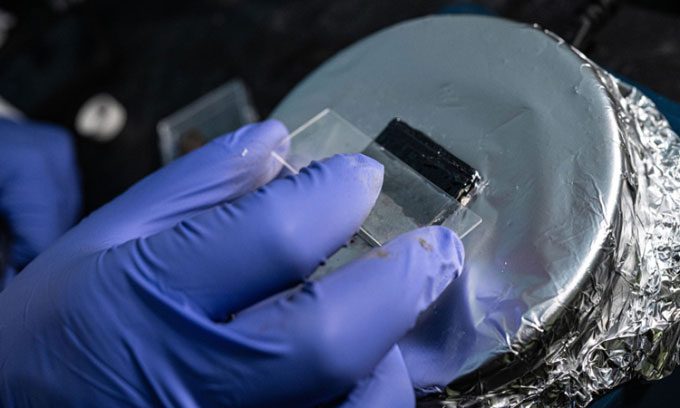

Scientists at Rice University apply a new coating to steel to prevent corrosion. (Photo: Jeff Fitlow/Rice University)

The new coating is made from a lightweight sulfur-selenium compound that possesses the characteristics desired by researchers. It has the ability to block moisture and chloride, similar to zinc and chrome-based coatings, protecting steel in environments akin to seawater, while also resisting microbial corrosion.

The research team identified these properties through a series of experiments. First, they submerged lightweight steel bars coated with the sulfur-selenium compound in seawater alongside uncoated steel for about a month. While the bare steel rusted severely, the coated steel showed no color change, demonstrating excellent oxidation resistance.

Next, they tested the coating against sulfate-reducing bacteria, known to significantly accelerate corrosion. They exposed both coated and uncoated samples to plankton and biofilms. This time, the coating continued to protect the steel, providing an inhibition efficiency of up to 99.99% according to the research team.

The most impressive capability discovered by the researchers may be its strong self-healing property. When they cut a piece of the compound in half and placed the two halves next to each other on a hot plate, they rejoined into a single layer within two minutes when heated to 70 degrees Celsius. Holes could also be sealed by heating to 130 degrees Celsius for 15 minutes. The material after healing provided the same level of protection to the steel as when it was intact.

“If the compound is punctured, it will heal itself. If a quick recovery is needed, we can assist by applying heat. However, most thick samples will self-heal over time,” said Muhammad Rahman, a member of the research team.

With its flexible properties, the new compound is not only suitable for protecting steel in aquatic environments but also for flexible electronic devices. The team believes that the new compound offers better insulation than most flexible materials and is more pliable than most insulating materials. They are continuing experiments with various versions of the new material to suit different types of steel and explore different coating techniques. The research has been published in the journal Advanced Materials.