Instead of using synthetic methyl reducing agents for silver nanoparticles, Dr. Thúy utilized extracts from purple onions, which are safer and have the potential to create antibacterial biofilms.

In addition to its common use as an ingredient in dishes, purple onions are a rich source of flavonoid and polyphenol antioxidant compounds. Taking advantage of this food source, in 2019, Dr. Nguyễn Thị Thu Thúy (46 years old) from the University of Agriculture and Forestry in Ho Chi Minh City and her team discovered a method for producing silver nanoparticles from purple onion extract.

Dr. Thúy explained that the process of synthesizing metal nanoparticles typically involves using methyl reducing agents. If these agents remain in the nanoparticles, they can cause toxicity. To address this, Dr. Thúy and her team replaced methyl reducing agents with natural compounds found in purple onions.

Purple onions are a common food source that can be used to synthesize silver nanoparticles.

In their research on purple onions, scientists found that gallic acid, quercetin, and eriodictyol possess antibacterial properties. The team extracted 3 ml of the extract and stored it at a temperature of 4 degrees Celsius to preserve the activity of the compounds.

The extract was then mixed with a silver nitrate (AgNO3) solution at a concentration of 1 mM. This is considered an important precursor for creating disinfectants with properties that are easily soluble in water, facilitating the synthesis process.

From the resulting mixture, the team placed it in a stirring device for 60 minutes at a temperature of 70 degrees Celsius, until the color changed from light gray to dark brown. “This transformation indicates that silver nanoparticles have formed in the solution”, Dr. Thúy stated. The team conducted 30 tests for each concentration of silver nitrate solution and reaction temperature to determine the optimal ratio for harvesting the maximum amount of silver nanoparticles.

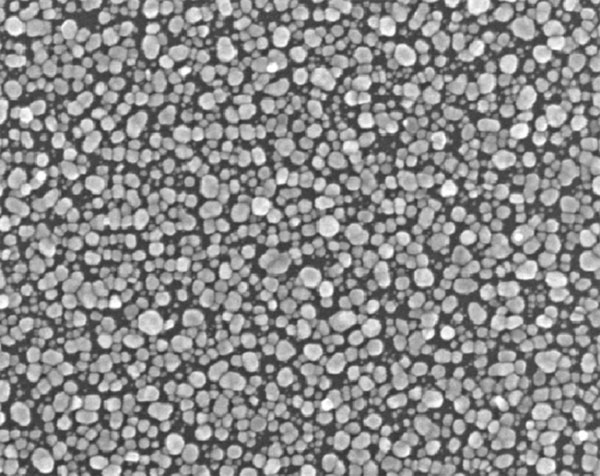

The silver nanoparticles were separated from the mixture using a centrifugation method at a speed of 10,000 revolutions per minute to condense them. After 10 minutes, the nanoparticles were odorless and pale yellow. When exposed to sunlight for about 60 minutes, the particles turned brown. Using spectroscopy and electron microscopy, the research team measured the silver nanoparticles to be 17 nanometers in size.

In this process, 3 ml (100 g) of onion extract can yield 6.8 ml of a mixture containing thousands of silver nanoparticles. These particles act by attacking the cell membranes of unicellular organisms (bacteria, fungi, algae) to inhibit their ability to transport oxygen into the cells, rendering them inactive.

Silver nanoparticles at a size of 500nm. (Photo: Provided by the author)

Silver nanoparticles synthesized in water typically range from 25 to 30 nanometers in size; however, smaller particles exhibit greater antibacterial and antimicrobial properties. Dr. Thúy noted that because common materials are used, the process of creating silver nanoparticles from purple onions can be scaled up if the team collaborates with manufacturing facilities or businesses.

This result enables Dr. Thúy and her colleagues to continue their plan to develop environmentally friendly food packaging films that can prevent bacterial contamination in food and serve as antibacterial layers for medical masks.

To create products applicable in everyday life, the next step for the team is to explore the antibacterial capabilities when combined with biodegradable polymer materials for the film, and to calculate the mixing process at the laboratory and later pilot scale.