Today, nuclear energy is produced through the fission process, with 415 reactors currently operational worldwide, primarily cooled by water.

“Nuclear energy is one of the safest, cleanest, least environmentally burdensome, and cheapest energy sources when considering the entire lifecycle of a nuclear power plant,” Rafael Mariano Grossi, Director General of the IAEA, stated at the 54th annual meeting of the World Economic Forum in Davos, Switzerland, January 2024.

The benefits of nuclear energy are increasingly recognized by environmental activists and leaders around the globe. At the COP28 conference in Dubai, leaders from 22 nations signed a declaration to triple global nuclear energy capacity by 2050 to meet climate goals and energy demands.

Tianwan Nuclear Power Plant in Jiangsu, China. (Photo: Xinhua).

“After 28 years of neglect, nuclear energy is finally getting attention at the world’s most important climate change conference, almost too late. As someone who once opposed nuclear energy but later changed my mind, I am pleased to see how much attitudes towards nuclear energy have changed,” said Zion Lights, former spokesperson for the Extinction Rebellion environmental movement in the UK.

How is Nuclear Energy Produced?

Nuclear energy is a form of energy released from the nucleus—the core of atoms, composed of protons and neutrons. This energy can be generated in two ways: fission (where the nucleus splits into several smaller parts), and fusion or thermonuclear (where nuclei combine).

Currently, the nuclear energy harnessed worldwide for electricity generation is produced through fission. Meanwhile, the technology for generating electricity from fusion is still in research and development (R&D) stages.

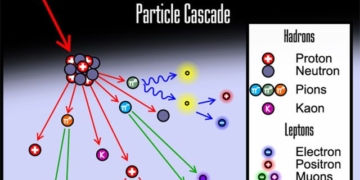

Nuclear fission is a reaction in which the nucleus of an atom splits into two or more smaller nuclei, while releasing energy. For instance, when struck by a neutron, the nucleus of uranium-235 may split into two smaller nuclei, potentially barium and krypton, along with 2 or 3 neutrons. These additional neutrons can collide with surrounding uranium-235 atoms, causing them to split and continue generating more neutrons, leading to a chain reaction in an instant.

Every time a reaction occurs, energy is released in the form of heat and radiation. This heat can be converted into electricity in a nuclear power plant. Inside a nuclear power plant, the reactor and equipment contain and control the chain reactions. The heat generated from the reaction heats the coolant of the reactor, usually water, creating steam. This steam is then directed to rotating turbines, which activate generators to produce electricity.

Notable Reactor Technologies Worldwide

According to the International Atomic Energy Agency (IAEA), as of November 13, 2024, there are 440 nuclear reactors globally, with 415 of them operational across 30 countries. The United States has the highest contribution with 94 reactors, totaling a generating capacity of 96.95 GW. Following are France (56 reactors, total capacity 61.37 GW), China (56 reactors, total capacity 54.15 GW), Russia (36 reactors, total capacity 26.8 GW), and South Korea (26 reactors, total capacity 25.82 GW).

Nuclear reactors come in various shapes and sizes, most large enough to supply power to major cities. Smaller reactor models are being developed to complement them.

Aside from a few reactors that use gas or metal for cooling, approximately 400 reactors worldwide, with capacities ranging from 30 to 1660 MW, are water-cooled. Current water-cooled reactors are divided into three main types: Pressurized Water Reactors (PWR), Boiling Water Reactors (BWR), and Pressurized Heavy Water Reactors (PHWR).

Watts Bar Nuclear Power Plant in Tennessee, USA, utilizes a Pressurized Water Reactor (PWR). (Photo: Energyeducation).

Pressurized Water Reactors (PWR) account for nearly 70% of the global reactor count, according to the World Nuclear Association (WNA). About 300 reactors are operational for electricity generation with a total capacity of 300 GW. Countries that commonly use PWRs include the United States, France, Japan, Russia, China, and South Korea.

PWRs use ordinary water as both coolant and moderator (the substance in the core that slows down neutrons released from fission to enable more fission reactions). This design features a primary coolant loop that runs through the reactor core and a secondary loop where the steam generated helps turn the turbines. The water in the primary loop is kept from boiling by high pressure. The water in the secondary loop is under less pressure, allowing it to boil and turn the turbines to generate electricity.

PWRs require only ordinary water as a moderator instead of expensive heavy water. They are also very stable, as they tend to reduce output as temperature increases. PWRs can operate with a core containing less fissile material, reducing the risk of uncontrolled power surges, thereby enhancing safety.

However, they do have some limitations, such as requiring very robust piping and pressure vessels, making PWR construction quite costly. Most reactors need to be refueled approximately every 18 months and must temporarily shut down for several weeks for refueling. Hot water from the primary loop with dissolved boric acid can corrode stainless steel, leading to corrosion products (which are radioactive) flowing through the primary loop. This reduces the reactor’s lifespan and necessitates special systems to filter corrosion products.

Boiling Water Reactors (BWR) are the second most common type globally, accounting for 15% with about 60 reactors and a total capacity of 60 GW. Unlike PWRs, this design features a single loop where water is kept at a pressure that allows it to boil. The steam generated is fed directly into the turbine. BWRs are primarily distributed in the United States, Japan, and Sweden.

Due to having only one loop, the BWR design is simpler and easier to operate. The internal pressure in the reactor vessel is much lower than in a PWR since the water is allowed to boil. Thus, the vessel is lighter and does not need to withstand high pressures. BWRs do not use boric acid, which reduces corrosion in the reactor vessel and piping.

However, BWRs require more complex calculations to adjust nuclear fuel consumption during operation, and the reactor core needs more equipment. Another drawback is that the steam produced is slightly radioactive, necessitating careful shielding of the piping and turbine.

With nearly 50 reactors and accounting for 11% globally, Pressurized Heavy Water Reactors (PHWR) are the third most common type of nuclear power reactor, contributing a total capacity of 25 GW. This design uses heavy water, a chemically distinct form of water, for cooling and controlling nuclear reactions. Heavy water reactors are mainly constructed in Canada and India.

A significant advantage of PHWRs is their ability to refuel while in operation, enhancing availability. Thanks to heavy water, PHWRs can use natural uranium as fuel instead of enriched uranium like PWRs and BWRs. Additionally, these reactors are considered very safe.

Despite lower fuel costs, PHWRs incur additional costs for producing heavy water. Furthermore, the energy content of natural uranium is lower than that of enriched uranium, requiring more frequent fuel replacements. The increased fuel flow through the reactor also leads to higher volumes of used fuel compared to reactors using enriched uranium.

Beloyarsk Nuclear Power Plant in Russia featuring two sodium-cooled fast reactors. (Photo: Rosatom).

Most reactors today use water to cool the core, but scientists are still researching and developing reactors that use liquid metals, molten salts, or gases as coolants. Developing these could lead to more efficient nuclear power generation with exciting new applications. Many non-water reactors have successfully operated for years, primarily at the experimental level.

For example, Liquid Metal Fast Reactors (LMFR) use liquid metals such as sodium and lead to cool the core. They can use uranium fuel in metal form instead of the more common ceramic form and can also use recycled nuclear waste. The rare fast reactors currently in operation are BN-600 and BN-800, both cooled by sodium. Both are located at the Beloyarsk Nuclear Power Plant in Russia.