Rare Earth Elements May Not Be Crucial for Electric Vehicles: A New Discovery Promises Enhanced Engine Performance and Environmental Protection.

German auto parts manufacturer Mahle has introduced a magnet-free induction motor, which aims to eliminate the pollution associated with rare earth mining.

The company’s MCT magnet-free motor ensures energy transmission through induction, providing high durability and outstanding efficiency exceeding 95%.

Magnet-free electric motors promise to revolutionize the electric car industry in the future (Image: Valeo).

Additionally, Valeo, a multinational company based in France, has developed a magnet-free EESM motor, featuring a 30% increase in efficiency and a 30% reduction in carbon emissions (during production) compared to traditional electric motors.

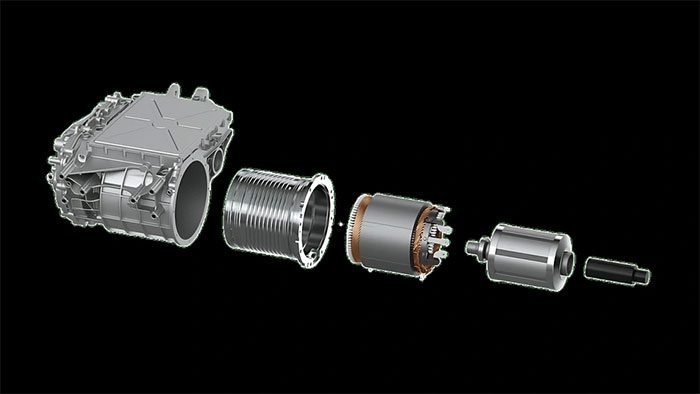

The collaboration between the two companies has led to a groundbreaking innovation: the iBEE magnet-free electric motor, which combines Mahle’s contactless rotor with Valeo’s control technology.

The new iBEE motor boasts an impressive output of up to 350 kW, with real-world testing scheduled for later this year.

Both companies hope to commercialize this invention within the next few years, which is expected to transform the electric vehicle industry.

Beyond performance, the iBEE motor significantly contributes to reducing ecological impact, achieving a 40% reduction in CO2 emissions and paving the way for more sustainable car manufacturing.

A magnet-free motor operates without relying on permanent magnets for motion; instead of utilizing rare earth elements like neodymium to generate a magnetic field, these motors use electromagnetic induction.

This technology minimizes environmental impact by avoiding the need for rare earth mining.

In a magnet-free motor, motion is generated by an electromagnetic field through copper coils or other conductive materials.

The rotor, the moving part of the motor, is powered without direct contact, thanks to systems like Mahle’s MCT (magnet-free contactless transmission system).

Energy is transmitted through induction, which resists mechanical wear, thereby enhancing the motor’s durability.

Magnet-free motors provide an ecological alternative by eliminating the use of rare earth materials, whose mining is often environmentally damaging.

In addition to reducing carbon emissions from electric vehicles by 30 to 40%, this technology decreases reliance on rare earth resources and production costs while maintaining high energy efficiency.