With the potential to create smartphones as thin as credit cards and electric vehicles with a range increase of up to 70%, this technology is ushering in a new revolution in the energy storage industry.

Researchers have developed a type of “structural battery” that promises to change the way electric vehicles and electronic devices are manufactured. This battery not only provides energy but also can replace the structural framework of electric cars and devices, significantly reducing weight and enhancing performance. According to experts, this technology could lead to new products like smartphones as thin as credit cards and laptops that weigh less than half of their current counterparts, while also increasing the range of electric vehicles by up to 70%.

Structural Batteries and Weight Reduction

Currently, electric vehicles rely heavily on large lithium-ion battery packs to ensure long ranges. However, a research team at Chalmers University of Technology in Sweden has aimed to create a battery that serves not only as a power source but also as a load-bearing material to support the vehicle’s structure. This opens up the potential for developing lighter vehicles while maintaining rigidity and operational capability.

This new battery is called “structural battery” and is made from carbon fiber composite materials. Carbon fibers are known for their light weight, strength, and high load-bearing capacity, and in the Chalmers team’s research, they serve not only as structural material but also as electrode material. This allows the structural battery to both store energy and reduce the overall weight of the electric vehicle.

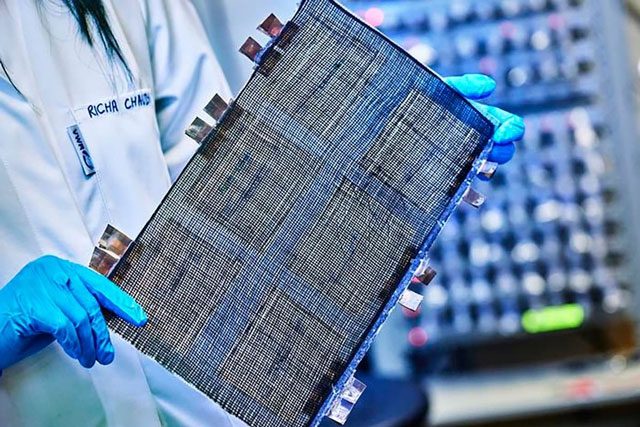

Carbon structural battery developed at Chalmers University of Technology, Sweden.

Performance of Structural Batteries

The structural battery developed by the research team has an energy density of 30 Wh/kg, which, while not as high as modern battery packs in electric vehicles, can significantly enhance overall performance when considering the entire mass of the vehicle, including the chassis. For instance, the battery pack of the Hyundai Ioniq 6 has a density of 153 Wh/kg, but that is the density of the battery alone, not accounting for the weight of the vehicle frame.

By applying structural batteries, manufacturers can utilize this formula to reduce the product’s weight or add more batteries into the freed space, thereby increasing energy storage capacity. This could help electric vehicles travel further and make electronic devices lighter and more efficient.

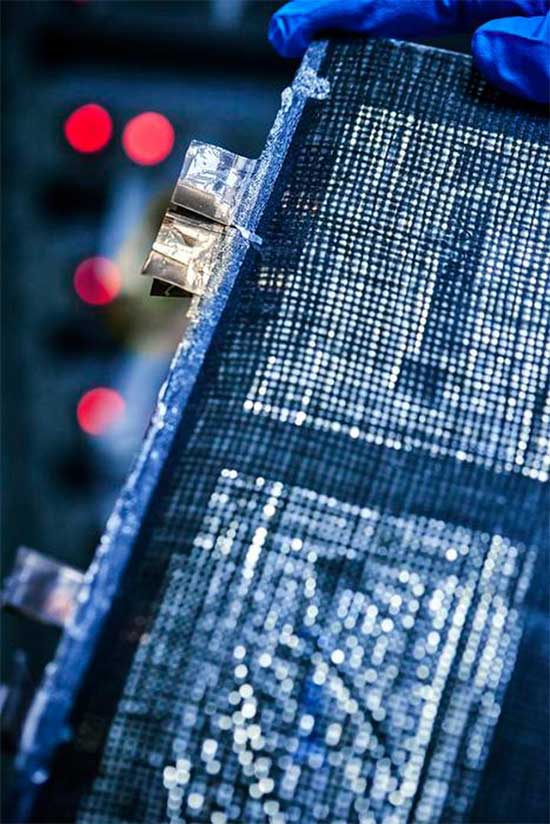

Carbon-based batteries promise to store energy and support loads like aluminum.

Revolutionizing the Electric Vehicle Industry

Professor Leif Asp, the leader of the research team, shared that this technology could create significant breakthroughs for the electric vehicle industry. “If electric vehicles are equipped with structural batteries, they could travel up to 70% further than they do currently,” he said. This means consumers could experience electric vehicles with wider ranges, lighter weights, and a more environmentally friendly profile.

A key aspect of structural batteries is eliminating heavy components like copper current collectors and metals such as cobalt, which raise environmental and human health concerns during extraction. Instead, the carbon fibers in the battery take on the role of both the anode and cathode, enhancing performance while reducing weight.

Design and Safety of Structural Batteries

This new structural battery is not only lighter but also safer. Instead of using liquid electrolytes as in conventional lithium-ion batteries, structural batteries use solid-state electrolytes, which reduce the risk of fire and explosion. However, the research team is still working to improve the ion mobility through this electrolyte to meet the high energy demands in large commercial applications.

Currently, structural batteries are still in the laboratory testing phase and require several more years of research before they can be mass-produced. However, the progress made is quite encouraging. Asp and his team have increased the size of the structural battery prototype and boosted its elastic modulus from 25 gigapascals to 70 gigapascals, giving it rigidity comparable to aluminum while being much lighter.

Researchers Zhenyuan Xia, Richa Chaudhary, and Professor Leif Asp have studied energy storage concepts for many years.

Commercialization and Future Applications

Chalmers University has partnered with Chalmers Ventures, a venture capital company in Gothenburg, to establish Sinonus with the goal of commercializing structural battery technology. Sinonus aims to develop products such as cars, electronic devices, and wind turbine blades based on this volumeless energy storage technology.

Professor Asp hopes that, in the near future, devices like smartphones and laptops will be significantly thinner and lighter, potentially weighing only half of their current weight. He also believes that structural battery technology will become crucial in industries with high energy storage demands, such as transportation and aviation.

Structural batteries have the potential to revolutionize the electric vehicle and electronic device industries, with capabilities to reduce weight, increase performance, and open up new product design opportunities. Although there are still many challenges ahead, this technology is on the rise and may become a key solution for reducing emissions and moving towards a sustainable energy future.