|

|

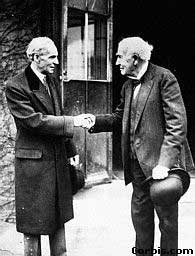

Henry Ford & Thomas Edison |

In around 1896, Henry Ford attended a meeting with the employees of the Edison Company in New York. At the party, Ford was introduced to the renowned inventor Thomas Edison by Alex Dow, the director of the Detroit Electric Company. He was presented as the man who had just invented an oil-powered automobile. This innovative work caught Edison’s attention, and he encouraged Ford to sketch out his vehicle. Ford quickly took the menu, flipped it over, and doodled some drawings. Upon seeing the components of the motor vehicle, Edison exclaimed: “You’re on the right path, an automobile that fuels itself, what a great idea, keep going!”.

After the party, Ford felt incredibly inspired. Thanks to Edison’s encouraging remarks, he relentlessly pursued improvements in automotive machinery, eventually founding the Ford Motor Company seven years later.

Henry Ford was not the first to invent the automobile, but he was the first to develop a mass-production system to meet market demand for automobiles. At that time, automobiles were considered a luxury, and manufacturers focused on creating expensive “toys” for the wealthy. Ford had a different vision. He believed that cars should be simple, durable, lightweight, and easy to assemble, with prices accessible to the middle class. These principles were applied to his famous Model T.

Ford established assembly lines that reduced the time needed to assemble a car from 14 hours to just 93 minutes. Across the United States, he set up manufacturing facilities, and from 1917 to 1927, nearly half of all cars made in the U.S. bore the Ford brand. For the Model T, production rates reached 10 cars every 16 minutes, and over 19 years, 15 million units were produced. Additionally, prices dropped significantly, from $850 in 1908 to $550 in 1913, $440 in 1915, and $290 by 1924.

Among all industrial ventures in the United States, the Model T was a tremendous success. James Couzens, the first commercial director of the Ford Motor Company, wanted to sell his shares to his sister, Rosetta Hauss, for $200. Although she was initially uninterested, she eventually agreed to purchase them for $100, not realizing that ten years later, the shares would yield $95,000. In 1919, when Ford sought to buy back small shares, Rosetta sold them for $260,000, having initially bought them for $100. Others, like lawyers Horace Rackham and John Anderson, who invested $10,000, later profited $25 million! Even Alex Dow regretted not purchasing shares in the Ford Motor Company, as the power of technology was unforeseen.

Henry Ford’s Early Years.

|

|

Young Henry Ford |

Henry Ford was born in 1863 in Dearborn, Michigan, to a father of Irish descent and a mother of Dutch descent. He was a courageous and wild character, with a reputation as a determined industrialist. As a boy, he became fascinated with automobiles while sitting beside his father in a horse-drawn wagon filled with hay, traveling on the roads of Dearborn, Michigan. At the age of 13, he was astonished to see a car driving in the opposite direction without a horse to pull it. His immediate reaction was to jump down, run over to inspect the vehicle closely, and ask the driver about it.

From that day on, Henry lost all interest in farming. He asked his father to allow him to learn the trade of a machinist. He repaired numerous tractors and harvesters and even sought to set up a small sawmill.

In 1891, Henry Ford took a mechanical position at the Detroit Electric Company, part of the Edison Illuminating Company. He explained to his wife that he was content with the low salary because it allowed him to learn about electricity, which was crucial for the automobile he had been researching for many years. His new job required Clara to leave their newly built home in Dearborn and move, but she never complained. Henry had explained to her many times about a horseless carriage, and she believed that success would come. Meanwhile, Henry was so engrossed in his fascination with engines that he often forgot paydays at the Edison Company.

In the 1880s, engineers began applying small engines to vehicles. On January 29, 1886, Karl Benz received a patent for a type of vehicle powered by raw fuel, and the following year, he demonstrated it in Mannheim, Germany. In the United States, Charles and Frank Duryea completed the first gasoline-powered automobile in 1893 in Springfield, Massachusetts. Meanwhile, on Christmas Eve of 1893, when his son Edsel was just seven years old, Henry Ford completed a single-cylinder gas engine. He set up the engine in the kitchen, and Clara assisted him in starting and adjusting it. Soon after, Ford built a two-cylinder engine. The coal shed became his workshop. On June 4, 1896, Henry Ford finished his first automobile and took it for a test drive on Grand River Avenue, but it stalled when he reached Washington Street.

At that time, automobile manufacturers often promoted their vehicles through races, so to attract public attention, Henry Ford constructed a 26-horsepower race car in 1901 to compete against Alexander Winton, a leading automobile manufacturer from Ohio. In a 10-mile race held in Gross Point, Michigan, Ford’s car won the prize. Following this success, Ford and a group of 12 investors embarked on establishing the Ford Motor Company with an initial capital of $100,000, including $28,000 in cash. By 1903, the Ford factory employed 125 workers, producing 1,700 cars across three models, each priced at $850. For that time, the Ford car, weighing nearly 600 kilograms, was among the lightest and cheapest, making it easy to sell. Thanks to this prosperity, the company’s capital increased by 1,000 percent within just four years.

At that time, automobile manufacturers often promoted their vehicles through races, so to attract public attention, Henry Ford constructed a 26-horsepower race car in 1901 to compete against Alexander Winton, a leading automobile manufacturer from Ohio. In a 10-mile race held in Gross Point, Michigan, Ford’s car won the prize. Following this success, Ford and a group of 12 investors embarked on establishing the Ford Motor Company with an initial capital of $100,000, including $28,000 in cash. By 1903, the Ford factory employed 125 workers, producing 1,700 cars across three models, each priced at $850. For that time, the Ford car, weighing nearly 600 kilograms, was among the lightest and cheapest, making it easy to sell. Thanks to this prosperity, the company’s capital increased by 1,000 percent within just four years.

At Ford Motor Company, Henry Ford owned the majority of the shares. The second-largest shareholder was James Couzens, who had previously served as Alexander Malcomson’s secretary and later became the General Manager of the company, eventually rising to Vice President and Treasurer, playing a pivotal role in the production of the Model T.

While managing the Ford automobile company, Henry Ford was deeply concerned about the cost of the vehicle and was reluctant to manufacture expensive models. He used his influence to reduce the number of cars produced in 1906, thus saving the Ford Company during the economic downturn of 1907. Ford also decided to create a new, sturdy, and affordable car model.

In the winter of 1906, Henry Ford allocated a separate section of 12 x 15 feet in the factory on Piquette Avenue in Detroit to research the Model T. He spent two years examining materials and manufacturing methods for the new type of automobile. During a car race in Florida, Ford inspected a damaged vehicle made in France and noticed that many components were made of an unusual steel. The Ford engineering team was certain that the French used a vanadium alloy, which was lighter and could withstand up to 170,000 lbs of stress, while American steel could only bear a maximum of 60,000 lbs. Ford then invited a metallurgist to produce vanadium steel for the Model T. As a result, during that era, vanadium alloy was exclusively used for high-end French automobiles and the Ford Model T. This made the Model T resilient to damage without breaking.

From October 1, 1908, with the amount of $850, customers could purchase a Model T car, weighing approximately 1,200 lbs, equipped with a robust 4-cylinder engine delivering 20 horsepower. It featured 2 speeds, was easy to drive, and included other characteristics such as simplicity and sturdiness. After the first year of production, 10,000 cars were sold, setting a new record. In 1909, entrepreneur Robert Guggenheim sponsored a car race from New York to Seattle, and only 2 Model T cars reached the finish line, prompting Guggenheim to state, “I believe Mr. Ford knows the answer to what a popular car is.”

In the early years, Model T cars were manufactured at the Piquette Avenue plant using the same methods as other automobiles. However, the rising demand for Ford vehicles led Henry Ford to consider establishing a new factory with an innovative production system.

During his many years as the company’s President, Henry Ford maintained a substantial cash reserve, allowing him to advocate for a new policy without external pressures. Consequently, the new automobile manufacturing plant in Highland Park was designed by leading industrial architect Albert Kahn and inaugurated in 1910. This facility spanned 62 acres, and its enormous scale led John D. Rockefeller, chairman of Standard Oil, to describe the Highland Park factory as “the industrial miracle of the age.”

During his many years as the company’s President, Henry Ford maintained a substantial cash reserve, allowing him to advocate for a new policy without external pressures. Consequently, the new automobile manufacturing plant in Highland Park was designed by leading industrial architect Albert Kahn and inaugurated in 1910. This facility spanned 62 acres, and its enormous scale led John D. Rockefeller, chairman of Standard Oil, to describe the Highland Park factory as “the industrial miracle of the age.”

In the early years, the assembly process in this factory was organized in a top-down manner, starting from the fourth floor, where conveyor belts delivered various parts to assembly workers. On the third floor, the car frames were fitted with wheels, and completed vehicles were assembled on the ground floor, lined up in front of the office. In the first three years, production volume increased by 100%, from 19,000 units in 1910 to 34,000 units in 1911, and reached 78,440 units in 1912.

In 1909, Henry Ford declared, “I will make the automobile democratic, everyone will be able to afford one, and almost everyone will have a car.” The initial selling price of the Model T was $850, but it dropped to $575 by 1912, which was lower than the average annual income of ordinary Americans. Henry Ford sacrificed part of his profits to increase sales volume, resulting in 248,000 Ford cars sold in 1913. Thanks to a new systematic economic policy and strategy, Ford Company’s revenue rose from $3 million in 1909 to $25 million in 1914. In 1908, Ford cars accounted for just 9.4% of the market, but this figure jumped to 48% by 1914. The Model T from Ford dominated the global automobile market.

———————————————–

Stay tuned for: “Henry Ford: The Workers’ Friend“