(khoahoc.tv) – With their unique neck structure, ants do not need “high hopes” to lift heavy objects.

Researchers have discovered that the neck joints of a common American field ant can withstand astonishing pressure. Such joints could inspire future robots to mimic the ability of ants to lift heavy loads both on Earth and in space.

These high hopes could help move a rubber tree (similar to the song High Hopes from the 1959 film The Hole in the Head, which won an Oscar for Best Original Song), but the true mystery behind the legendary strength of ants likely lies within the tiny neck joints of these small insects.

“Ants are truly impressive mechanical systems,” said Carlos Castro, an assistant professor of mechanical and aerospace engineering at Ohio State University. “Before starting the experiments, we subjectively estimated that they could withstand a weight approximately 1,000 times their body weight, but the reality is even more remarkable.”

Engineers are investigating whether such joints could enable future robots to lift heavy objects like ants do, both on land and in space.

Other researchers have observed ants in the field for a long time and guessed that they could lift objects weighing hundreds of times their body weight or even more, based on the weight of leaves or prey they carry. However, Castro and his colleagues took a different approach.

They dissected the ants into individual parts.

“Just like with any mechanical system, if you want to understand how they work, you need to break down each part,” Castro explained. “In this case, it may sound cruel, but we anesthetized them before proceeding.”

The engineers examined the Allegheny mound ant (Formica exsectoides) to see if it resembled a type of device they wanted to redesign: they tested the moving parts of this ant and the materials that make up those parts.

They chose this particular ant species because it is commonly found in the eastern United States and can be easily obtained from the university’s insect research laboratory. This is an average field ant and is not particularly remarkable for its lifting ability.

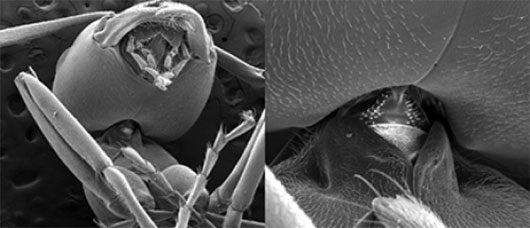

They took images of the ants using electron microscopy and computed tomography (CT) scans. First, the ants were placed in a refrigerator to anesthetize them before being glued onto a specially designed centrifuge to measure the force needed to deform the neck and ultimately detach the head from the body.

The centrifuges operated on the same principle as a game called Rotor. In this game, a circular room spins until centrifugal force pins the body against the walls, and players are flung off their standing spots. In the case of the ants, their heads were glued to the floor of the centrifuge, so when it spun, their bodies could be pulled away until their necks snapped.

The centrifuges spun at hundreds of revolutions per second, continuously increasing pressure on the ants. At a centrifugal force corresponding to about 350 times the ants’ body weight, their neck joints began to stretch and their bodies elongated. The ants’ necks broke under a force of approximately 3,400 to 5,000 times their average body weight.

CT scans revealed the soft tissue structure of the neck and its connection to the hard exoskeleton of the ant’s head and body. Electron microscopy images showed that each part of the head-neck-thorax joint was covered with an unusual texture, with structures resembling bumps or hairs radiating from various locations.

“Other insects also possess similar microstructures, and we believe they may play some mechanical role,” Castro noted. “These microstructures could adjust how soft tissues and exoskeletons interact to minimize pressure and optimize mechanical function. They might create friction or stabilize a moving part against another part.”

Another important property of the design appears to be the gradual transition between the soft material of the neck and the hard material of the head. Such transitions usually create areas of high-pressure concentration, but ants have a gradual and categorized transition between materials that enhances efficiency—a design feature that could be beneficial for artificial designs.

“Now that we understand the limits of endurance of these ants and how their mechanical response occurs under load, we want to find out how they move. What supports their heads? What changes when ants carry loads in different directions?”

One day, this research might lead to the invention of tiny robots that combine hard and soft components, similar to the bodies of ants. Much of today’s work involves assembling small robots, individual devices that can work together. However, a challenging issue will arise if researchers try to create larger robots based on similar designs, Castro explained.

Ants are incredibly strong on a small scale because their bodies are so light. Inside their hard exoskeletons, their muscles do not need to support much weight, allowing them to freely use all their strength to lift other objects. Humans, conversely, carry a relatively heavy load due to their body weight. With human muscles adding to body weight, we do not have much strength left to lift other objects.

On a human scale, however, ants triumph through basic physics. Their body weight increases with their overall volume, while their muscle strength only increases with surface area. Therefore, a tiny creature like an ant, if it were real and not from a horror film, would likely not be able to carry heavy loads like ants do.

“A large robot based on that design could transport and pull cargo in a zero-gravity state, so one day we could design a giant ant robot in space, or at least something inspired by ants,” Castro said.

In the meantime, engineers will study the anatomy of ants in detail—possibly using magnetic resonance imaging. Computer simulations will also help answer the question of how to scale up similar structures.

Blaine Lilly, a professor of mechanical and aerospace engineering, began this research project alongside former student Vienny Nguyen. Nguyen completed her master’s degree with this project and is now a robotics engineer at NASA’s Johnson Space Center, where she is assisting in designing the Valkyrie robot for DARPA’s Robotics Challenge. Nguyen, an Ohio State University student, has recently joined Castro’s research team, where she is responsible for analyzing the surface structure of ants in greater detail. Castro and Lilly have also begun collaborating with Noriko Katsube, another professor of mechanical and aerospace engineering, who is an expert in the mechanical modeling of biological materials.