From a petroleum engineering background, Dr. Nguyễn Ngọc Tuân has shifted his research focus to biomaterials, successfully developing a biodegradable artificial ligament with his team to promote ligament tissue regeneration.

Dr. Nguyễn Ngọc Tuân (34 years old), from École Normale Supérieure (ENS-PSL), Paris (France), and his colleagues are pursuing new techniques in the field of tissue engineering. This research continues from the development project of biodegradable artificial ligaments that he initiated at Sorbonne Paris Nord University (France) in 2017.

“Many organ tissues in the body, when damaged or lost, find it very difficult or impossible to heal. Thus, regenerating these damaged tissues becomes an intriguing problem for scientists,” Dr. Tuân told the reporter.

The biodegradable artificial ligament is developed from biopolymer fibers (polycaprolactone and previously polyethylene terephthalate) that can enhance the regeneration of torn ligament tissue. It is used to temporarily replace damaged ligaments to stabilize the knee joint and serves as a framework to promote the regeneration of tissue cells into new ligaments.

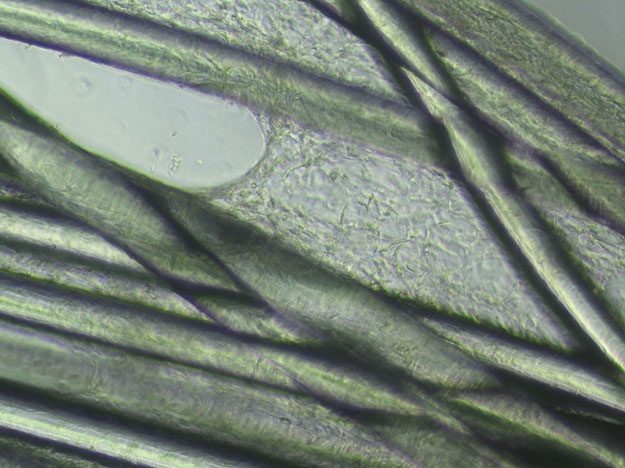

Biopolymer fiber bundle of the artificial ligament was tested for biological activity on fibroblast cells in vitro after 10 days, showing significant cell adhesion and growth. (Photo: Research Team).

Interestingly, the polymer fibers will decompose slowly in the body without causing cytotoxicity during the regeneration of the new ligament, thus eliminating the need for surgical removal. This is a beneficial solution for patients with knee-related injuries, commonly seen in athletes, especially football players, heavy laborers, or those who exercise incorrectly.

Results from the research indicate the potential to promote faster recovery from injuries, with lower risks, greater effectiveness, and reduced costs compared to traditional tissue grafting surgical methods. The research has been considered a “breakthrough in the field of tissue engineering and regenerative medicine,” published in international journals such as Polymer Degradation and Stability (2020-2021, Elsevier), Scientific Reports (2021, Springer-Nature), and Biointerphases (2020, American Institute of Physics).

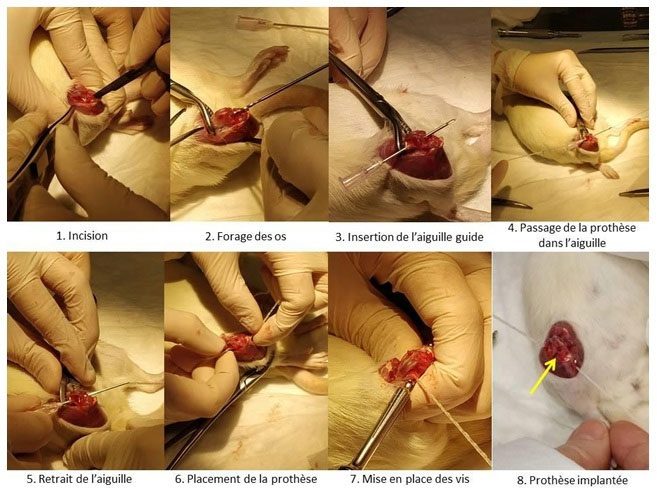

Process of implanting artificial ligaments on experimental mice. (Photo: Research Team).

Dr. Tuân stated that the biggest challenge is to “meet the stringent requirements for implantation into the body,” because the materials need to be biocompatible with cells, non-cytotoxic, and have mechanical properties suitable for the tissue. For instance, biopolymer fibers for artificial ligaments need to withstand tensile forces, twisting, and the weight from the body on the knee joint to keep the joints stable. Additionally, there is a requirement to enhance cell adhesion and promote cell growth into target tissues.

To address this issue, the team activated the fiber surface by coating it with biologically active polystyrene sulfonate molecules through strong chemical bonding with cells. The research team employed ozonation techniques to control the complete coating of the 3D surfaces of the polymer bundles. The entire process underwent strict control over medical conditions before the product was tested in vitro and implanted in mice, sheep, and eventually humans.

“The reproducibility of these materials is also a challenge that needs to be overcome,” he added. The materials must meet the requirements for functional stability, production, and pass rigorous tests from health organizations like the FDA (USA) or CE (Europe).

Professor Veronique from Sorbonne Paris Nord University, a member of the French Biomedical Engineering Association and the team leader, stated that anterior cruciate ligament (ACL) tears are among the most common sports injuries affecting athletes. Due to the poor healing ability of the ACL, surgical intervention is often required. According to the professor, the current technique of ligament reconstruction (autograft replacement) is considered the “gold standard.” However, over 50% of cases show risks of pain, bone necrosis at the attachment point, and lengthy recovery times (6 to 12 months). “Therefore, the development of biologically active and biodegradable artificial ligaments is a necessary direction to address these issues,” he said.

Currently, this technology is being utilized by Texinov and Movmedix companies for production and clinical trials in Europe and the USA. “The market for artificial ligaments that mimic natural ligaments, made from biocompatible materials, operates in vivo without causing systemic reactions in the body. Implanting artificial ligaments is a highly specialized technique recommended for athletes and patients needing high performance,” Dr. Julien Steinbrunn, Director of Research and Development at Movmedix, assessed.

Dr. Nguyễn Ngọc Tuân. (Photo: Provided).

Regenerative medicine research is an unexpected path for Dr. Tuân, who originally studied petroleum engineering. He recounts starting his pursuit of polymer material research as a student at Ba Ria University (Vung Tau). Thanks to support from the then head of the department, Associate Professor Dr. Nguyễn Văn Thông, he received a research scholarship for students from the university. “That was a turning point that guided me to pursue a research path later on,” he said.

In 2017, Dr. Tuân received a doctoral scholarship focusing on biomaterials for regenerating the anterior cruciate ligament of the knee, under the supervision of Professor Veronique Migonney at Sorbonne Paris Nord University. The research is part of the LIGA2BIO project from the Future Investment Program (PIA) funded by BPIfrance, in collaboration with biotechnology companies. After graduation, Dr. Tuân worked in the research and development department of a biotechnology company, CERAVER, before becoming a postdoctoral researcher at École Normale Supérieure, focusing on biomaterials and cell research.

Currently, he collaborates with research teams from Compiègne University of Technology (France) and Saarland University (Germany) on gene transfer and guided gene scaffolding for regenerating bone, cartilage, and ligament tissues.

“We aim to address the limitations of biomaterials for regenerating complex or irreparable organ tissues and train scientific personnel in this field,” he said.

Dr. Tuân further mentioned that Vietnam currently has many large research groups and biomaterials technology companies involved in this field. However, he sees the need for interdisciplinary research groups, such as chemistry, mechanics, biology, and medicine, to closely collaborate between research teams and manufacturing companies. “I am always looking for opportunities to collaborate and work with research teams in the field of tissue engineering in Vietnam.”