A team of scientists from Stanford University and the University of Amsterdam has created the world’s thinnest lens, measuring just three atoms thick.

The lens is designed to collect, bend, and focus light to a specific point. This magnifies objects for vision correction, allowing people to see very small things through microscopes or distant objects via telescopes. Lenses are typically made from curved glass or other transparent materials; for example, contact lenses are made from hydrogel.

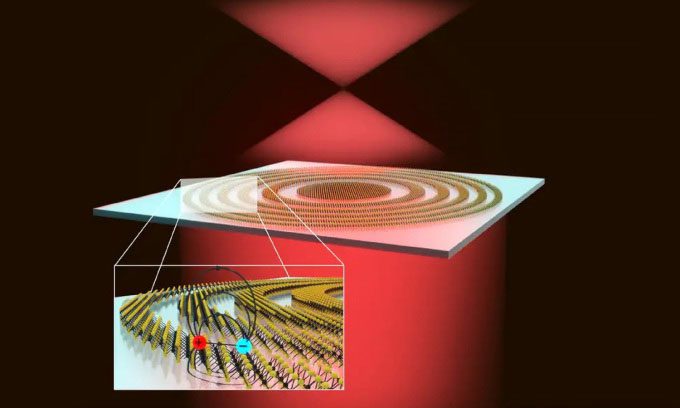

Diagram of the world’s thinnest lens. (Photo: Ludovica Guarneri/Thomas Bauer)

However, this classic design can make larger lenses thick and heavy, especially when made from glass. To save material, the Fresnel lens was invented in the 19th century, initially used in lighthouses. Fresnel lenses utilize multiple concentric rings of material to diffract light to a focal point. This reduces image clarity but allows the lens to be significantly thinner.

In a new study published in the journal Nano Letters, the team from Stanford University and the University of Amsterdam has developed a lens just 0.6 nanometers thick, or three atoms, as reported by New Atlas on June 1st. This is the thinnest lens ever made, surpassing the previous record set in 2016 with a lens that was 6.3 nanometers thick, approximately ten times thicker.

The new lens consists of concentric rings of tungsten disulfide, which absorb incoming red light and reflect it to a focal point one millimeter from the surface. The lens operates by creating short-lived quasiparticles known as “excitons.” These particles then decay and emit light. Because the lens selectively focuses only red light, other wavelengths pass through unaffected. This characteristic opens up several intriguing applications.

“The lens can be used in applications requiring an unobstructed view through the lens, while a small portion of the light can be harvested for information collection. This makes it ideal for wearable devices such as augmented reality (AR) glasses,” explains Jorik van de Groep, an expert at the University of Amsterdam and a member of the research team.

The research team stated that they will next explore whether this technology can be used to create complex coatings activated by small electrical pulses.