The recent transfer of old aircraft from China to the United States for dismantling has sparked significant public interest. Many are questioning why China, a nation rapidly advancing in aviation technology, cannot dismantle its own old aircraft and must rely on foreign assistance.

In 2017, the large passenger aircraft C919, independently developed by China, successfully completed its test flight, marking a new chapter for the Chinese civil aviation industry. By the end of 2022, this domestically produced large aircraft was officially put into commercial operation by China Eastern Airlines.

With the commercialization of the C919, COMAC (Commercial Aircraft Corporation of China) has received numerous orders from various airlines. To date, orders for the C919 have exceeded 1,500 units. This figure not only reflects the robust development of China’s civil aviation industry but also highlights China’s manufacturing strength.

China currently has only a few aircraft dismantling facilities. (Illustrative photo).

The Chinese aviation industry has witnessed explosive growth over the past few decades, leading to an increasing demand for aircraft dismantling services. However, this growth has not been accompanied by corresponding investments in infrastructure and skilled labor for this sector. Currently, China has only a limited number of dismantling facilities, primarily focused on domestic aircraft. These facilities lack modern equipment and skilled personnel, resulting in inefficient and costly aircraft dismantling.

Interestingly, while China’s civil aviation sector is making rapid advancements, a phenomenon cannot be overlooked – the issue of “retired” aircraft. Statistics show that from 2020 to 2040, China is expected to retire up to 4,000 aircraft from commercial service.

Why is there such a large scale of retirement? There are two main reasons:

- Firstly, although aircraft are designed with a lifespan of 25 to 30 years, maintenance costs significantly increase over time.

- Secondly, to ensure flight safety, Chinese civil airlines often retire commercial aircraft after 14 years of service.

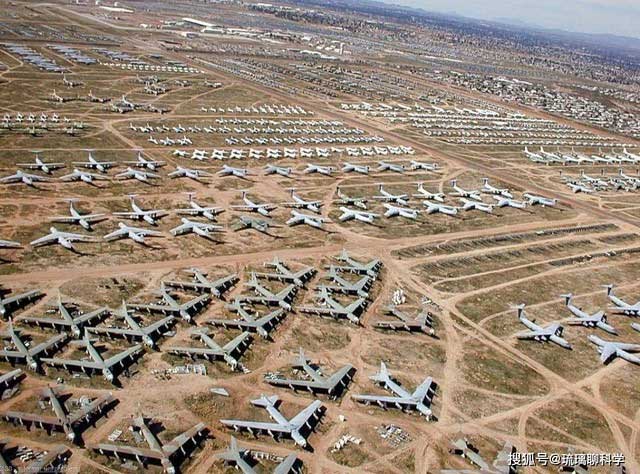

Interestingly, these retired passenger aircraft are not dismantled in China but are sent across the ocean to Davis-Monthan Air Force Base in the United States. This vast base, covering 2,600 acres, serves not only as a storage facility for civilian aircraft but also houses numerous military aircraft such as F-16s and F-15s, earning it the nickname “The Boneyard.”

Dismantling aircraft in China may pose environmental regulation risks. (Illustrative photo).

The dismantling of aircraft presents numerous environmental pollution risks, including fuel leaks, hazardous chemicals, and noise. Consequently, countries impose strict regulations on aircraft dismantling activities to ensure environmental protection. China has similar regulations; however, enforcement of these regulations is limited. Therefore, dismantling aircraft in China may pose risks of violating environmental regulations, leading to penalties for dismantling companies.

Why does China choose to send its “retired” aircraft to the U.S. for dismantling? Several considerations lie behind this choice. First is the climate factor. The dry climate at Davis-Monthan Air Force Base effectively slows down the corrosion and aging process of aircraft. Additionally, the transportation routes around this base are highly convenient, connecting to various federal highways, facilitating easy access for large transport vehicles.

Some might argue that China, with its vast territory and abundant resources, should find a suitable location domestically to establish a similar dismantling facility. In reality, this involves more complex considerations. Besides geographical and climatic conditions, transportation costs, professional teams, and skill levels are also critical factors.

Dismantling aircraft in the U.S. can save costs and time for Chinese airlines. (Illustrative photo).

The United States has a long-established aircraft dismantling industry with modern infrastructure, skilled personnel, and safe and efficient dismantling processes. Therefore, dismantling aircraft in the U.S. can save costs and time for Chinese airlines.

When establishing aircraft dismantling facilities in China, the first challenge is high transportation costs. The economically developed southeastern coastal areas of China contrast with the western desert regions that have favorable climates but would incur high transportation costs for dismantled parts. More importantly, aircraft dismantling is not a simple task; it requires a professional appraisal team and dismantling crew. These teams must possess extensive experience and exceptional skills to ensure that every component is utilized to its full potential.

The appraisal team is responsible for accurately tracking global market price fluctuations in real-time and valuing the aircraft and their components. This not only requires extensive expertise but also the ability to observe the market long-term and accumulate experience. The dismantling team must carefully disassemble designated components as per buyer requests to ensure they remain intact. Any negligence during this process could result in costly losses.

Dismantling aircraft requires a professional appraisal team and dismantling crew. (Illustrative photo).

China is making efforts to develop its domestic aircraft dismantling technology, but it still faces many limitations compared to advanced countries like the U.S. Some of the most advanced dismantling technologies, such as composite material recycling technology, have yet to be widely implemented in China. Therefore, dismantling aircraft in the U.S. can help Chinese airlines access the latest dismantling technologies and improve operational efficiency.

In addition to expert teams, licensing is also a crucial part of the dismantling process. Only a professional dismantling team with a “145 Maintenance License” can meet the legal certification requirements to ensure that dismantled parts are of reliable origin and quality.

China is striving to develop its domestic aircraft dismantling technology. (Illustrative photo).

Notably, “The Boneyard” is not only used for dismantling and selling parts. It also has a mission of preparing for war. Here, a large number of third and fourth generation aircraft are stored and can quickly be deployed into combat after minimal maintenance. The importance of this strategic reserve force is evident, reflecting a nation’s foundational strength in air power and rapid response capability.

In conclusion, many complex factors contribute to the phenomenon of retired passenger aircraft from China being sent to the U.S. for dismantling. Everything from climate conditions, transportation layout, to professional teams and skill levels are essential considerations.