|

| Staff installing traffic sign pole in red and white colors |

For those who frequently travel on the streets of Hanoi, such as Thanh Nien Street, Nghi Tam Street, and 19-8 Square in front of the Grand Opera House, it is easy to notice that the dividers here consistently maintain their striking red and white colors, unlike the typical dividers found on the streets of Hanoi.

However, very few people are aware that these are not the familiar reinforced concrete blocks.

For the first time, products made from polymer composite (PC) materials have appeared on the streets of Hanoi, and for the first time in Vietnam, not only are they used as dividers replacing reinforced concrete, but they are also being used for guardrails and traffic signs.

This innovation stems from a research project by a team at the Polymer Materials Research Center (Hanoi University of Science and Technology), which recently won third prize at the VN Scientific and Technological Innovation Award (VIFOTEC) 2005.

According to Dr. Bạch Trọng Phúc, the project leader, the common use of reinforced concrete dividers has many drawbacks: they are costly to maintain since they require repainting every six months, pose danger to road users, lack aesthetic appeal, and are complicated and cumbersome to move.

Dr. Phúc noted that the PC products for dividers, guardrails, and traffic signs simultaneously address the shortcomings of similar products made from reinforced concrete: enhancing durability, withstanding environmental factors such as humidity, temperature, UV rays affecting color stability, chemical impacts, and fire resistance.

The scientists at the Polymer Materials Research Center also discovered the optimal mixing ratio for color powders to meet the specific color requirements in traffic and withstand weather conditions.

|

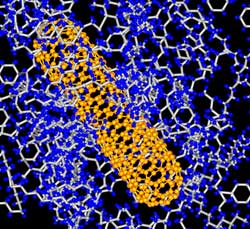

| Chemical model of carbon nanotube – polymer composite |

Notably, the team successfully researched the use of some natural fibers (jute, bamboo) as reinforcement to partially replace fiberglass. The project has been recognized for its creativity in using surfactants to enhance the dispersion of powders in plastics, improving material properties and cost efficiency.

For the first time, using wet pressing technology, hollow, sealed, glossy PC divider blocks with three different colors on the same product have been utilized on several streets in Hanoi. The installation is very easy with the PC blocks being significantly lighter than concrete.

After installation, it is only necessary to pump water or sand into the hollow cores of the PC blocks to achieve the required weight for functioning as dividers and guardrails. When relocation is needed, one simply opens the valve and drains the water or sand. According to Dr. Phúc, as the production is still in the experimental stage on a small scale using manual methods, the cost of PC dividers is currently 1.5 to 2 times higher than those made of concrete, while guardrails and signs are comparable to those made of metal. With a large-scale production process and investment in synchronized machinery, costs could be significantly reduced.

The economic efficiency also lies in the fact that due to the lightweight nature of PC products, the costs for installation, maintenance, and routine care (painting, cleaning, etc.) are very low compared to concrete and steel. The widespread use of PC products on city streets also provides a higher level of safety for people and vehicles involved in traffic and enhances the aesthetic quality of the streets.

With the aim of promoting the widespread application of PC products, the authors from the Polymer Materials Research Center (Hanoi University of Science and Technology) are ready to transfer technology for large-scale production using automated machinery. Dr. Phúc estimates that an investment of about 10 billion VND would be sufficient to establish a production line for PC dividers or guardrails.

Currently, after Hanoi, Da Nang has also begun to manufacture and install PC dividers on its roads and intersections.

Red and white polymer composite divider

Article and photos by: THANH HÀ