Tunnels are constructed using various methods, depending on their type, purpose, and the materials employed. The most common method is to build a tunnel above ground and then submerge it underwater. This is done by creating segments of the tunnel on land and then sealing them with walls. These segments are then placed in a long, narrow trench that has been dredged and prepared beforehand.

In the past, journeys over water, while fascinating, could often be life-threatening. A ship or ferry could easily be engulfed by rising tides and raging storms. In 1954, five ferries carrying tourists in the Tsugaru Strait, the body of water between Hokkaido and Aomori Prefecture in Japan, faced disaster when confronted by a storm.

Given this situation, building a bridge was not considered an effective alternative since storm winds could still destroy it. The safest alternative, albeit the most challenging, was to construct an underwater tunnel.

There are many ways to build underwater tunnels.

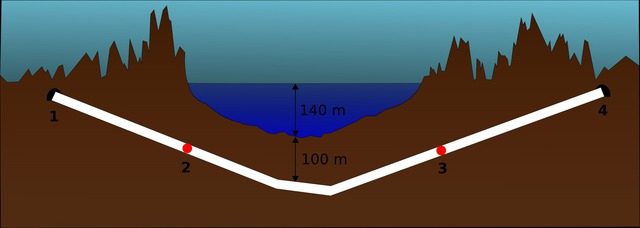

However, in 1998, the Japanese government decided to construct an underwater tunnel, which was considered the deepest and longest tunnel at that time. The Seikan Tunnel lies at a depth of 140 meters below the seabed and stretches nearly 54 kilometers! Naturally, the question arises: how were these engineering marvels constructed?

The world’s first underwater tunnel was built beneath the River Thames flowing through London. In the early 19th century, London was the trade center of Europe and much of the rest of the world at that time. The ports were congested with coal ships and other goods, and the roads were overwhelmed with horse-drawn carriages, leading to increasingly concerning traffic jams, especially as the industrial sector was growing. Therefore, a solution was needed to enhance trade and travel without increasing traffic flow.

At that time, the idea of building an underwater tunnel seemed incredibly challenging; it was almost considered a concept from science fiction. However, engineers realized that it was also the most effective solution. Of course, constructing an underwater tunnel came with risks: ocean mud and water pressure could seep through gaps and collapse the entire tunnel, which would be a disaster.

The world’s first underwater tunnel was built beneath the River Thames.

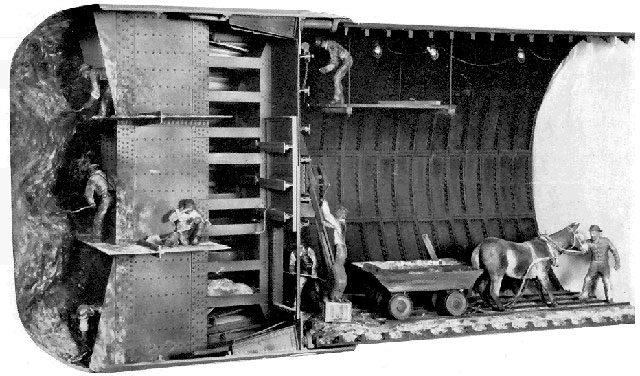

However, in 1818, Marc Brunel, recognized as one of the most talented engineers in England, developed a device that could excavate tunnels beneath the seabed without allowing mud or water to seep in! He utilized what is now known as the “Tunnel Shield.”

The Thames Tunnel between Wapping and Rotherhithe was not excavated using large drilling machines but was literally dug by hand by workers. As the tunnel shield moved forward, workers at the front would dig, while those behind would lay bricks along the newly formed tunnel, reinforcing them with concrete to create a tunnel capable of accommodating horse-drawn vehicles—and later, trains. Workers had to create two discharge openings, one for handling mud and sand, and another for water.

Initially, it was estimated that the tunnel would take only three years to complete, but in reality, it took about 18 years to finish. To this day, this tunnel remains a crucial part of London’s railway network. For a time, it was regarded as the eighth wonder of the world.

The tunnel shield, or shield tunneling machine, is a protective structure used in tunneling through soft soil or slurry, to maintain the stability of the tunnel walls while the reinforced concrete wall structure is being constructed. Initially, it served a simple function as a shield to hold back the earth during manual tunneling, but with mechanization in tunneling construction, it was improved to include the function of excavating the tunnel and became a specialized digging machine. In practice, the tunnel shield serves as a temporary support structure for the tunnel while it is being excavated.

However, as scientific and engineering advancements continued, instead of constructing and excavating tunnels simultaneously, the method shifted to building a tunnel above ground and then submerging it underwater.

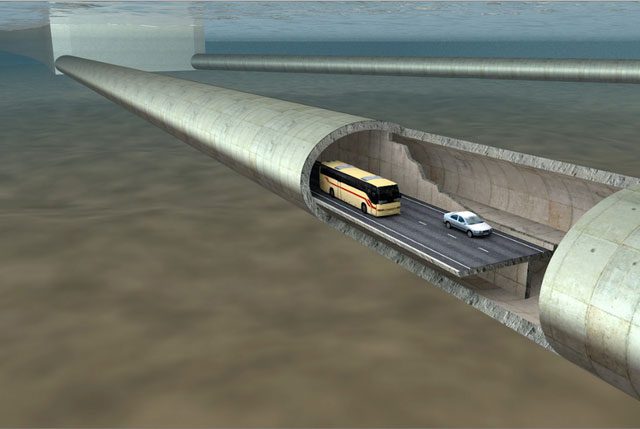

A tunnel constructed in this manner is built in segments. The concrete segments are sealed with walls and then submerged underwater, placed in a long, narrow chamber running along the length of the tunnel to be built. These chambers are developed by dredging and preparing the trench before constructing the segments. Each segment is then connected to form the tunnel.

Nowadays, with advancements in science, a tunnel is built in segments.

The Ted Williams Tunnel, connecting the southern part of Boston to Logan Airport, was constructed in this manner. The tunnel consists of twelve segments, each 325 feet long, which are connected to form the tunnel. Even more remarkably, each of these segments has already been fully constructed with roads!

Although this technique is cost-effective, it also has several drawbacks:

- First, engineers must be extremely careful when submerging the sections, as even a slight misalignment can lead to catastrophic consequences.

- Second, while submerged tunnels are constructed in trenches, there is a possibility that some sections exposed to the water’s surface may become exposed. These gaps could result in terrible accidents if struck by sinking ships or anchors.

- Third, there are clearly adverse impacts from dredging the channel bed, affecting the environment and ecosystem.

However, the most convenient method is to use drilling machines, provided they are very large. The Channel Tunnel connecting the UK and northern France was constructed using gigantic machines known as Tunnel Boring Machines (TBM). TBMs, also referred to as “moles,” are machines that tunnel by cutting through rock and strata using rapidly rotating blades.

The process of building an underwater tunnel.

Of course, the downside of this method is its high cost. Moreover, a single machine costing millions of dollars is not sufficient to construct a tunnel. The Channel Tunnel connecting the UK and northern France required 11 machines for its construction. Therefore, it can be said that no technique can be considered absolutely the best.