A team of MIT experts has developed a 3D printing technology that is 10 times faster than similar metal 3D printing processes, although it still has aesthetic limitations.

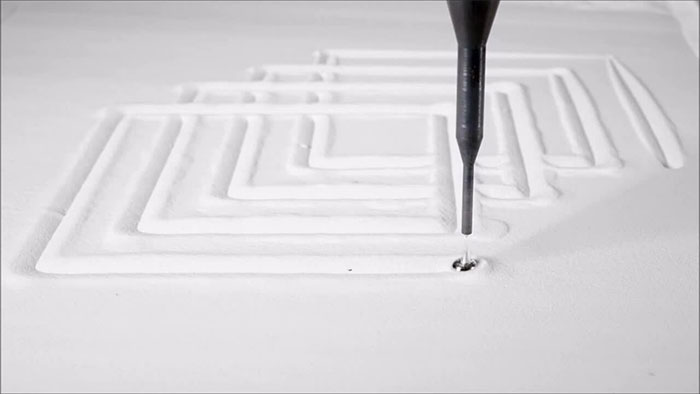

The process of 3D printing furniture parts using liquid metal. (Video: MIT).

In a recent study, the Massachusetts Institute of Technology (MIT) has successfully 3D printed furniture components, such as frames and legs for tables and chairs, using liquid metal, achieving sturdy parts in just a few minutes, Design Boom reported on January 26. The printing process begins with the spray of liquid metal, specifically aluminum, following a pre-designed shape. The liquid metal quickly solidifies and takes form.

Researchers state that liquid metal printing (LMP) technology allows for 3D printing to be 10 times faster compared to similar metal 3D printing processes. Melting metal can also be more efficient than some other methods, as metal is more readily available, with a large supply of scrap material that can be recycled.

While LMP shows great promise, it also has its limitations, according to Associate Professor Skylar Tibbits from the Department of Architecture at MIT and a member of the research team. For instance, this technology enables rapid printing of large objects, but the resolution and aesthetic quality are not high. Printed objects exhibit a distinctly rough and uneven surface.

Liquid metal printing technology allows for 3D printing to be 10 times faster than similar metal 3D printing processes.

“However, most of the things built in the human world, such as furniture and buildings, do not require extremely high resolution. Meanwhile, speed, scale, repeatability, and energy consumption are all important parameters,” Skylar Tibbits explained.

The MIT team also created a machine capable of melting aluminum, maintaining this liquid metal, and then spraying it from a ceramic nozzle in a predetermined shape. “Molten aluminum can destroy almost anything in its path. Initially, we used stainless steel nozzles, then switched to titanium, and finally chose ceramic. However, even ceramic nozzles can clog because the heat is not always evenly distributed at the nozzle tip,” said Zain Karsan, a PhD student at ETH Zurich.

LMP facilitates rapid 3D printing of furniture parts and other objects using liquid metal. Since molten aluminum cools in just a few minutes, users can utilize the products immediately after fabrication. The research team also found that the larger the amount of aluminum they melt, the faster the printer can operate. In the future, they aim to find ways to maintain a stable temperature in the nozzle and prevent the liquid metal from sticking together, while also improving material flow and seeking design solutions to enhance the uniformity and smoothness of the products.