After its launch in 2022, soundproof walls made from waste straw have been improved by a Vietnamese startup to reduce water absorption, increase fire resistance, and facilitate installation.

By researching the extraction of hollow cellulose fibers from straw, Dr. Vu Viet Dung (35 years old, from Nam Dinh) and his team have created soundproof panels that meet construction industry standards. The product made its debut in 2022, garnering attention in the industry, especially for its environmentally friendly green product qualities.

Dr. Vu Viet Dung stated that over the past two years, he has received numerous contributions aimed at improving the product. Taking these suggestions into account, he established a small workshop of 80m2 to transform the research product from the laboratory into a commercial offering, contributing to the market with sustainable soundproofing solutions made from green materials.

The author with his product at an event in 2022. (Photo: Ha An)

The research has also led to several upgrades in product properties, including moisture and fire resistance. According to tests by Dr. Vu Viet Dung, water no longer penetrates the straw soundproof panels. When exposed to high flames from a torch, the material does not ignite easily and does not spread flames when the fire is extinguished.

Mr. Dung noted that recently, fire and explosions have become significant issues attracting public attention. Addressing this problem will help the product gain easier acceptance in construction. With the high humidity of tropical climates like Vietnam, products that do not absorb water will have a longer lifespan.

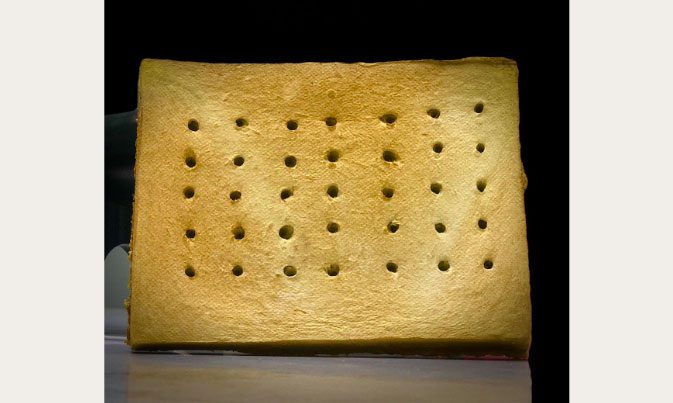

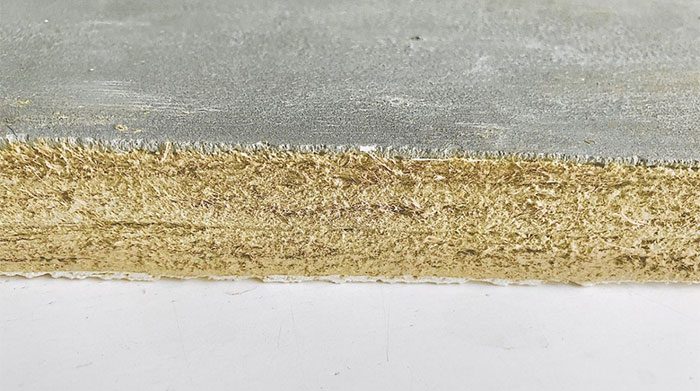

Testing the water and fire resistance of the straw fiber soundproof panel. (Source: NVCC).

In 2023, following improvements in product properties, several new straw product samples were created with dimensions of 600 x 600 mm. All products utilize tightly compressed straw cores to reduce hollowness, supplemented with rigid surfaces on both sides to enhance soundproofing and thermal insulation capabilities. With their lightweight design, they are easy to transport, cut, and install at any construction site.

Soundproof and thermal insulation products have been produced. (Photo: NVCC).

Utilizing the sound-absorbing characteristics of the product with its hollow cellulose fibers, sound energy enters, dissipates, and is retained before escaping. With significant hollowness, the sound absorption capacity can reach up to 90%. The sound-absorbing material is suitable for widespread use in large spaces such as theaters, auditoriums, stages, or concert halls. Another benefit is that these natural, chemical-free products will ensure better health for users.

Tests have demonstrated that this material achieves a sound insulation coefficient (Transmission loss [dB]) of 65 dB at low frequencies below 1,000 Hz. This frequency range is commonly encountered in daily life, including noise from karaoke bars, traffic, machinery, and construction sites.

According to Mr. Dung, the soundproof and thermal insulation product made from straw fibers has added beneficial properties such as water resistance and fire retardancy, making it suitable for installation in sound-absorbing projects (auditoriums, lecture halls…) and for soundproofing homes, hotels, and more.