An iron (or flat iron) is an essential and familiar household item for every family. This tool is used to smooth out the wrinkles in fabrics, helping clothes look neater. Today, irons have become indispensable in daily life.

However, have you ever wondered how people in ancient times managed to iron their clothes? How was the iron invented? What is its development history?

Let’s take a journey back over 2000 years to ancient Rome to explore the formation and evolution of the iron to answer these questions.

Ancient Times – Primitive Tools for Smoothing Clothes

Thousands of years ago, humans had the need to remove wrinkles or create pleats in their clothing. In ancient Greece (around 400 BC), ironing was typically performed by slaves due to the labor-intensive and time-consuming nature of the work. This was a luxury demand of the upper class, as only the wealthy owned many clothes and slaves. During this time, people used heated iron clamps to create pleats in linen garments.

Simulation of Greek clothing smoothing tools

By the time of the Roman Empire, people began using a hand-held iron to smooth out clothes. It resembled a flat metal paddle. Wrinkles in clothing were removed by continuously pressing the fabric with the “paddle”. Another tool used during this period was the “prelum,” which was a wooden device shaped like a press. Two wooden boards were stacked on top of each other and could be tightened with a wooden screw. Clothes were placed between the two boards, and then the screw was tightened to create pressure, removing the wrinkles.

Hand-held iron used by Romans

Ancient Chinese people also used some iron tools to smooth their clothes. The most common tool was an iron pan shaped like a large spoon. Hot coals or sand were placed inside the spoon to heat the bottom. This heated bottom was then moved over the surface of the clothing to smooth it out.

Iron pan used by ancient Chinese to smooth clothes

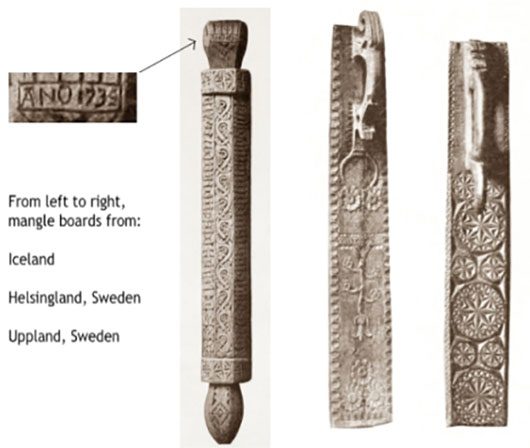

Around the 10th century AD, the Vikings from Scandinavia began creating “irons” made of glass. They believed that glass could glide over the surface of clothing more quickly and easily than iron. Rounded glass rods were heated near the fireplace and then used to move across the fabric.

Vikings using heated glass to iron clothes

12th to 14th Century – The First Signs of the Iron

By the 12th century, trade between the East and West began to develop, leading to significant advancements in fashion, including the use of starch to create more elaborate clothing. People started wearing garments with intricate buttons or ruffled collars. The demand for a tool capable of generating heat and pressure became increasingly urgent.

In the Netherlands around the 1200s, an iron tool shaped like a small boat was created for ironing clothes. However, due to limitations in metalworking technology, these tools were not finely crafted or sharp-edged, making it difficult to create precise ironing lines. This tool resembled the base of modern irons.

One hundred years later, in the 1300s, advancements in metal production techniques allowed for the creation of more refined tools. At this time, garments with ruffled collars were popular. In Italy, a tool known as Goffering, which resembled a horizontal iron tube on a stand, was used. After heating the iron tube, fabric was rolled around it to create the pleated ruffled collar that was very popular during the Renaissance. This process was very time-consuming, so only the nobility could afford to wear such styles.

Tool for creating pleated collars in Italy

Later, to reduce the time and effort required for pleated collars, another tool called Fluter (the pleat tool) was introduced. This tool consisted of a base and a piece made of iron. Both contact surfaces were carved with evenly spaced grooves. The fabric was placed between the two iron pieces, and pressure was applied by hand to create even pleats. However, during this process, a cloth had to be placed between the contact surfaces to prevent the iron from dirtying the fabric. Additionally, another inconvenience was that each Fluter was designated for a specific style of pleated collar.

Video using Fluter to create pleats

15th to 19th Century – The First Primitive Iron Appears

By the 15th century, thanks to significant advancements in metalworking technology, the idea of a hollow iron that could contain coal for heating began to emerge. This was a hollow iron box with a handle, and the base was made smooth to glide easily over the fabric without leaving metallic stains. To heat the base, in addition to hot coal, one could also place heated bricks, a hot metal rod, or other items that could retain heat inside. Clothes could be directly ironed without needing to place a fabric underneath the iron box. This model became the prototype for the modern iron used today. However, the drawback of this iron model was its inability to retain heat for long, especially at the tip. Nevertheless, this iron model continued to be used for nearly 400 years.

The first shape of the iron with a separate heating element

When the Bessemer steel-making process was invented in the early 19th century, the remaining issues with previous iron models were largely resolved. People could manufacture irons made entirely of steel that could be heated by placing them on the stove. Heat was evenly distributed across the base, including the tip, allowing for ironing complex areas of garments like around buttons and collars. However, the drawback of irons at that time was that they still could not retain heat for long. After a certain period of ironing, they still needed to be placed back on the stove to reheat the base. This disrupted the ironing process and was quite time-consuming.

Solid steel iron

The 20th Century to Present – The Era of Innovations and Improvements in Modern Irons

Until the mid-19th century, the designs of irons were still dependent on blacksmiths and consumer feedback. There were several models of irons ready for commercialization, but they could not overcome the drawback of long waiting times for heating on the stove. In 1871, Mary Florence Potts, an American housewife, received a patent for a detachable handle for the iron. Potts’ invention allowed multiple iron bases to be pre-heated on the stove without the need to wait. When one base was sufficiently hot, users simply detached the handle and switched to a pre-heated base. Potts named this generation of irons the “Sad Iron.” According to records, the reason she named it “Sad” was due to its heavy weight, which always left her hands sore after working with it.

Sad Iron with Detachable Handle

From the 1800s, gas lines began to appear in most American homes. In 1874, the idea of creating a gas-powered iron was proposed, where a gas line was connected inside the iron. Gas was then ignited to heat the iron’s base. However, this method was quickly dismissed due to its dangerous nature, as gas could easily leak. Subsequently, alternatives such as gasoline, kerosene, candles, and various other fuels were used to heat the irons.

Gas-Powered Iron

Ten years after Mary Florence Potts’ invention, in the 1880s, electricity began to gain popularity in American households. In 1882, American inventor Henry W. Seeley received a patent for the “electric iron.” This was the first iron to use electricity to heat wires attached to its base. It was the first electric iron in history and the only household electronic invention of the 1860s. However, this electric iron was quite heavy, weighing up to 6 kg. The drawback of this first model was the inability to control temperature. By 1920, British inventor Joseph Myers improved the heat-conducting wire inside the iron into a temperature-controllable wire using an automatic regulator made from pure silver. This temperature control quickly became the standard for the next generations of irons.

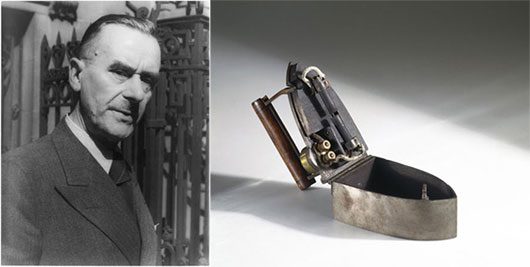

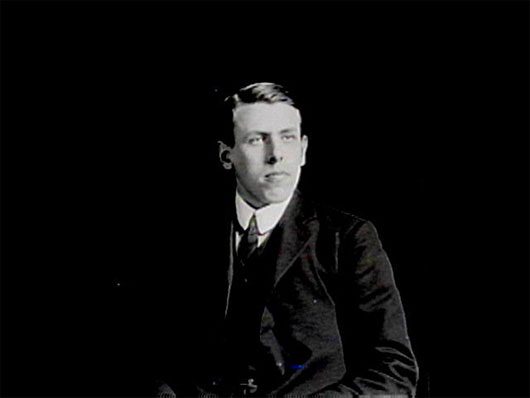

Inventor Henry W. Seeley (1861-1943) and the First Electric Iron

In the following years of the 20th century, electric irons became popular and transformed the way millions of homemakers across America flattened their clothes. However, electric irons still could not completely achieve perfectly smooth clothing. Users needed another innovation to elevate the ironing experience to a new level. Soon after, in 1926, architect Thomas Warren Sears (1880 – 1966) introduced the first steam iron. However, it wasn’t until the 1940s that the first steam irons were officially marketed by Eldec.

Architect Thomas Warren Sears (1880 – 1966). The First Steam Iron Inventor

Then, in 1995, the non-stick iron was officially introduced. This was a breakthrough in the development of modern irons that continues to this day. Following this, the materials used for the iron’s body changed, with manufacturers moving to create plastic-bodied irons for lighter weight. Subsequently, a series of improvements allowed irons to control temperature more accurately for various types of fabrics, along with many other valuable enhancements. By 1996, over 14 million irons had been sold, featuring a multitude of convenient functionalities.

Conclusion

Over 2000 years of significant improvements, starting from the crude metal pieces of the Romans, to the glass of the Vikings, accompanying the development of fashion and metallurgy during the Renaissance, to the invention of the simple handle by a housewife, followed by a series of important innovations, ultimately resulting in the iron that is so familiar in every household around the world. We can somewhat appreciate how ordinary items have such a long history of formation and development. We hope that through this article, you can gain a better understanding of the household items around you, making the task of laundry a bit more “enjoyable.”