Many companies recognize the potential for producing certain products in space, where factors such as low temperatures, microgravity, and vacuum conditions prevail.

For some startups, the most pressing question in the field of manufacturing today is: How can we fabricate computer components, harvest stem cells, and produce pharmaceuticals in space?

Manufacturing in space has already begun, at least at the research level, the Guardian reported on September 26. NASA has awarded $2 million to scientists to explore whether microgravity conditions can aid in the development of new gene and stem cell therapies. The American defense corporation Northrop Grumman is collaborating with a startup to produce semiconductors in space. An expert noted that by the end of this decade, humans will be using objects containing elements produced beyond Earth.

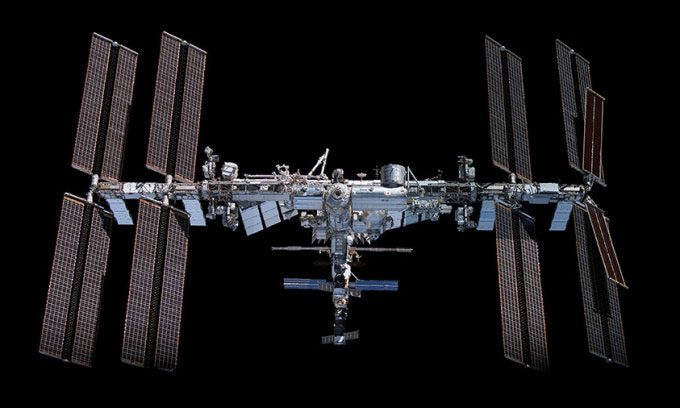

International Space Station (ISS) captured from SpaceX’s Crew Dragon. (Photo: NASA).

Benefits of Space Manufacturing

Billionaire Jeff Bezos believes that heavy manufacturing industries that pollute the atmosphere could operate far from Earth. “This may sound far-fetched, but it will happen,” he stated.

According to proponents of building manufacturing facilities in space, certain conditions in space—such as low temperatures, near-zero gravity, and vacuum—allow specific materials, like crystals, to be created with better quality than on Earth.

“Space is a much better place to carry out almost any industrial process. We live on a planet with gravity holding us down. We’ve created ovens, refrigerators, and vacuum pumps to help produce products on Earth, but if you go to space, you get those benefits for free,” said Joshua Western, CEO of Space Forge, a space technology manufacturer based in Wales.

Several pharmaceutical companies hope to produce new medications in space. Merck is collaborating with the International Space Station (ISS) to manufacture proteins in a microgravity environment. Astronauts conducting experiments for Merck found that the crystals grown for the cancer drug Keytruda were smaller and more uniform than those grown on Earth.

Researchers at Bristol Myers Squibb (BMS) are testing how to use resources generated off-planet to make medications more stable. According to Robert Garmise, Associate Director of Materials Science and Engineering at BMS, the company is working on various issues including immunology, fibrosis, cardiovascular diseases, and neuroscience.

Kevin Engelbert, Manager of NASA’s Space Manufacturing Applications portfolio, stated that the agency has been collaborating with commercial partners to realize off-Earth manufacturing since 2016. The goal is to develop a low Earth orbit economy and strengthen America’s leading position in the tech world.

In July, the American startup Varda Space Industries launched a craft into low Earth orbit. The craft is expected to become the first drug manufacturing facility in space, automatically producing ritonavir crystals, an antiviral used to treat HIV.

However, as the spacecraft was preparing to land in Utah, the Federal Aviation Administration (FAA) and the U.S. Air Force denied Varda’s request to return to Earth. According to an FAA spokesperson, Varda did not have a reentry license prior to launching its vehicle into space. Varda requested the FAA to reconsider its decision on September 8, and that request is currently pending.

In July, Varda launched a spacecraft into low Earth orbit. (Photo: Varda Space Industries).

Growth Potential of Space Manufacturing

As more private spacecraft are launched, the demand for manufacturing in orbit will also increase, according to Sita Sonty, CEO of Space Tango, a company collaborating with the ISS to provide facilities that support research, development, and production in microgravity environments.

Space manufacturing companies predict that the number of products produced in space will rise significantly by the end of this decade as the ISS is no longer the only research facility in orbit (the ISS is expected to cease operations around 2030). The more private vehicles there are in space, the greater the opportunities for off-Earth manufacturing.

“With the emergence of more commercial space stations, the cost of going to space will decrease significantly. The more flights we have, the more drug samples and stem cells we can send to see how they perform in orbit. Before long, we will see commercializable applications,” Sonty noted.