A group of British scientists has created the world’s thinnest spaghetti, which is about 200 times thinner than a human hair and even narrower than certain wavelengths of light.

Researchers at University College London (UCL) have recently developed “nanopasta” – a super-thin spaghetti made using a technique called electrospinning, where a mixture of flour and liquid is drawn through a tiny opening by an electrode.

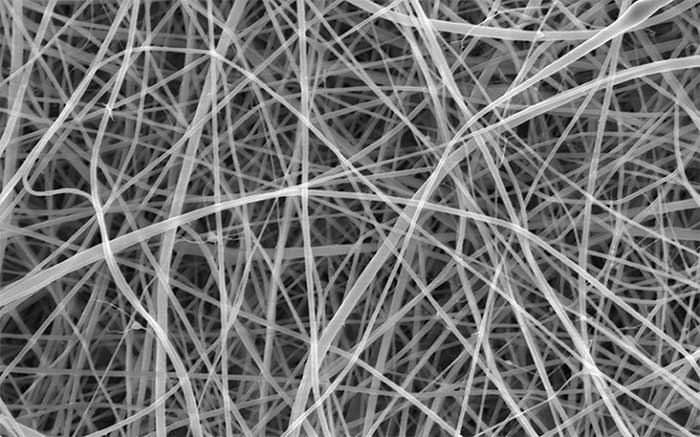

Nanopasta fibers under a scanning electron microscope. (Source: UCL).

These nanopasta fibers have a width of 372 nanometers (billionths of a meter), which is 200 times smaller than the average width of a human hair, and according to reports from UCL, they are even thinner than some wavelengths of light.

Dr. Adam Clancy, a co-author of the study, stated: “Spaghetti is made by forcing a mixture of water and flour through metal holes. We use a similar method, but the flour and water mixture is pushed through ultra-fine holes using electric charge. It’s really spaghetti, but much smaller.”

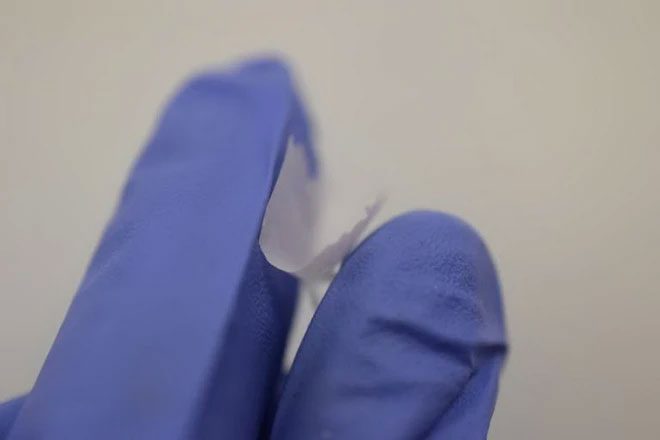

The newly created nanopasta forms a sheet of nanofibers about 2cm in diameter that is visible, but each individual fiber is too thin to be clearly captured by any camera or optical microscope. They can only be observed using a scanning electron microscope (SEM).

A sheet of nanopasta with a diameter of approximately 2cm. (Source: UCL)

Previously, the record for the thinnest pasta known was held by su filindeu, meaning “God’s thread,” created by a craftsman from Sardinia. These “God’s threads” have an astonishing width of 400 microns, yet they are still over 1,000 times thicker than the nanopasta developed by the British scientists.

The research team stated that they do not intend to create nanopasta for consumption, as it would cook “in less than a second.” Instead, this experiment is useful for creating environmentally friendly nanofibers for use in healthcare.

Professor Gareth Williams, another co-author of the study, noted: “Nanofibers, such as those made from starch, have potential applications in wound dressings because they are highly porous. Additionally, nanofibers are also being studied for use as scaffolds for tissue regeneration, as they mimic the extracellular matrix – a network of proteins and other molecules that cells build to support themselves.”

According to the research team at UCL, nanofibers are typically produced by extracting starch from plant cells and then refining it. However, this process is very complex and requires a lot of energy and water.

The method developed by UCL scientists to create nanofibers directly from starch-rich components like flour, a basic ingredient for pasta, is more environmentally friendly.

The researchers used flour and formic acid to make nanopasta instead of water because formic acid breaks down the giant helical chains that make up starch (cooking has a similar effect, breaking down starch to make pasta easier to digest).

The research team also had to carefully warm the mixture for several hours before gradually cooling it down to ensure the mixture had the right viscosity.

Dr. Clancy explained: “Starch is a promising material for use because it is abundant and renewable – it is the second largest biomass source on Earth, after cellulose – and it is biodegradable, meaning it can break down within the body.”

The study on nanopasta was published in the journal Nanoscale Advances.