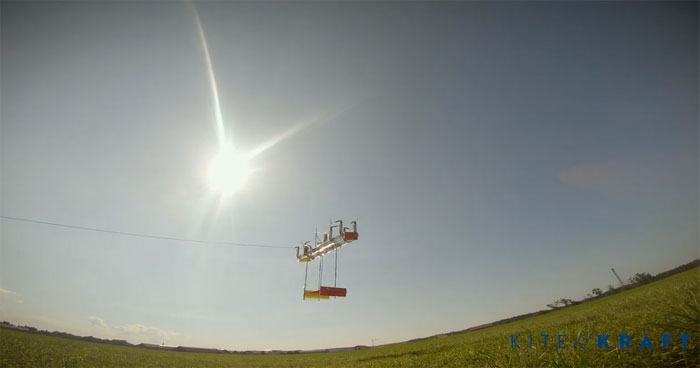

Kitekraft’s Kite-Shaped Wind Turbine Design Reduces Construction Costs and is Easy to Implement in Hard-to-Reach Areas.

Kitekraft tests a hovering wind turbine.

The startup company Kitekraft is developing a flying wind turbine that saves manufacturing materials up to 10 times compared to conventional wind turbines. The company recently announced a successful flight test, marking an important milestone toward producing its first 100 kW of electricity.

Kitekraft explains that the reduced material demand for the flying turbine, which uses a tether instead of a large tower, could cut energy costs by nearly half compared to traditional wind farms of similar scale. The carbon emissions from this design are also much lower than standard wind turbines, partly because large wind turbine towers are often transported by road.

To achieve this goal, Kitekraft has developed a kite that automatically generates energy through eight small rotors. The energy produced by the kite is transmitted through a cable to a ground station connected to the power grid. Kitekraft engineers state that their prototype generates the same amount of energy as the tip of a large wind turbine blade, the fastest-moving part of the rotor.

According to Florian Bauer, co-CEO of Kitekraft, this technology can be adapted for offshore use since it does not require foundations like traditional wind turbine towers installed on the seabed. If the wind is too strong, the kite can fly lower to avoid damaging the equipment.

After last month’s automated flight test, Max Isensee, co-founder of Kitekraft, stated that they are continuing to work towards a final design. Engineers have tested the operation of several new systems, including the wings, wind direction indicators, and flight control computers during the trials. Kitekraft plans to deploy the machine in small power grids of 20 – 100 kW on remote islands, where transporting infrastructure for large wind farms is less feasible.