Researchers have employed a “foaming” technique to make cellulose diacetate (CDA) more porous, enabling it to degrade 65-70% in seawater within approximately nine months.

For years, scientists have been searching for the fastest biodegradable plastic in marine environments as millions of tons of plastic enter the oceans each year. Now, a team from the Woods Hole Oceanographic Institution (WHOI) has identified CDA as the fastest degrading plastic in seawater, technically classified as a biodegradable plastic. They have further accelerated the degradation rate of this material using a simple modification technique called “foaming,” which enhances its porosity, as reported by New Atlas on October 18th.

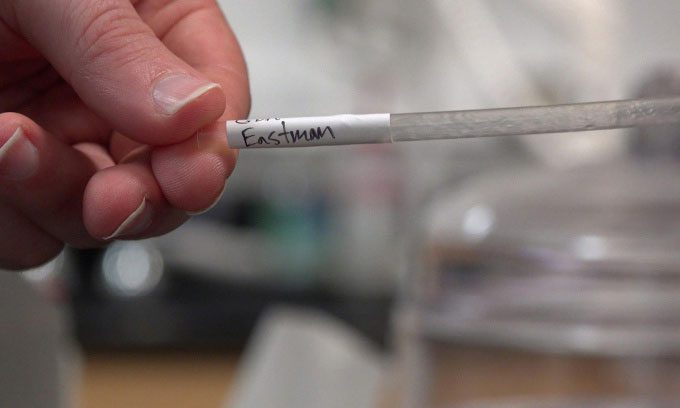

Experimental straw made from foamed CDA by Eastman to test its biodegradability. (Photo: WHOI).

CDA, or cellulose diacetate, is derived from cellulose, a natural polymer found in plant cell walls, particularly in cotton and wood pulp. CDA has been around since the late 1800s and is used in a wide range of products, from cigarette filters (the most common use) to eyeglass frames, photographic film, and millions of other items in daily life.

In this new study, the team managed to make foamed CDA degrade 15 times faster than its solid form, even outperforming paper. The findings were published in the journal ACS Publications.

“We have applied fundamental knowledge to design a new material that meets consumer needs while degrading faster in the ocean than any other plastic we know of, even faster than paper,” said Collin Ward, the lead author of the study.

During a 36-week experiment in continuously flowing seawater tanks, the foamed CDA lost 65-70% of its original mass. In contrast, a common plastic found in oceans worldwide, Styrofoam, showed no degradation over the same period.

In this study, Ward and other scientists from WHOI collaborated with the bioplastic manufacturing company Eastman, which provided materials, funding, and co-authorship. The research was conducted in a controlled laboratory environment, where the authors regulated light, temperature, and various other factors to simulate ocean conditions.

This new research will aid industries in reducing their use of traditional plastics and moving towards more environmentally friendly alternatives. The success of foamed CDA indicates that this material could be utilized in numerous products, helping to decrease the amount of non-biodegradable plastic waste in the ocean. Eastman has already produced a biodegradable tray that can compost into organic matter from foamed CDA, replacing traditional Styrofoam trays used for meat packaging—trays that do not biodegrade in any natural environment, whether on land or in water.