A group of Forestry University students researches biological products, then drills holes in Aquilaria trees to produce agarwood.

With the aim of stimulating agarwood growth as an alternative to traditional and chemical methods, students Nguyen Hoang Anh, Nguyen Anh Dung, and Nguyen Duc Nam sought to selectively cultivate certain strains of fungi found in nature to create a biological product.

Since July 2020, under the guidance of Dr. Nguyen Thi Hong Gam, the research team has isolated five fungal strains capable of stimulating agarwood production, including: Penicillium, Aspergillus, Trichoderma, Fusarium solani, and Mucor. These fungal strains are known for their ability to produce cellulase and pectinase enzymes efficiently in a laboratory setting. The team successfully isolated and developed a biological product that stimulates agarwood production.

Experiments conducted at an agarwood garden in Huong Khe District (Ha Tinh) over an eight-month period recorded a 100% success rate for drilling holes in the trees, resulting in agarwood formations measuring 2.2 x 36 cm, with dark wood and a sweet, fragrant aroma of agarwood.

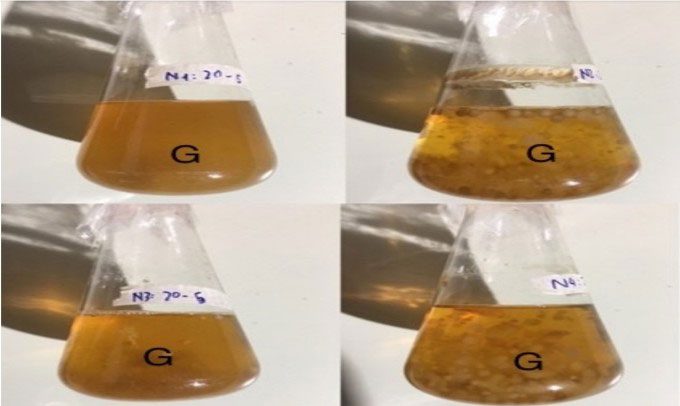

Biological products that enhance agarwood production mixed by the team in the laboratory. (Photo: NVCC)

Currently, there are many methods for producing agarwood, both manual and chemical. Nguyen Hoang Anh, the team leader, stated that creating natural agarwood through simple manual methods is easy to implement but has a low success rate. While chemical methods are more effective and can produce more agarwood in a shorter time, they leave harmful chemical residues that are not favored by consumers. Therefore, using fungal strains that can directly stimulate agarwood production in the tree is considered promising, with advantages such as a high success rate and no toxic chemical residues in the final product.

According to Hoang Anh, microorganisms can synthesize various enzymes that break down the compounds that make up the wood cells of Aquilaria trees. Consequently, the sturdy structure of the wood is gradually decomposed from the outside in. The characteristic of Aquilaria trees is their ability to synthesize compounds in the areas of damaged cells. “Creating a wound on the Aquilaria trunk and applying the biological product at that location will enhance the tree’s agarwood production,” Hoang Anh explained. The team is ready to transfer the technology for creating biological products to enterprises to apply the research results in practical production.

Drilling holes for agarwood production in Ha Tinh from the biological product developed by the team. (Photo: NVCC)

Dr. Nguyen Thi Hong Gam from the Institute of Forest Biotechnology (Forestry University) assessed, “the group’s research is quite systematic and can be applied immediately.” The fungal strains are readily available in nature, isolated and multiplied for more effective agarwood stimulation. However, the downside of the biological method is that it requires a long time to stimulate agarwood formation, and the quantity obtained from the trees may not be large.

Currently, agarwood trees are divided into two main types: natural and artificial. Artificial agarwood is formed under human influence. Typically, Aquilaria trees aged between 7 to 10 years are selected for drilling and grafting. After that, an additional five years are needed for the Aquilaria trees to produce agarwood. Similar to natural agarwood, artificial agarwood must also undergo formation and accumulation processes to create the final product.

In Vietnam, Aquilaria trees grow sporadically in forests from North to South, with a concentration in the provinces of Kon Tum, Kien Giang, Quang Nam, Da Nang, Quang Binh, Ha Tinh, and Phu Quoc Island. In Ha Tinh alone, as of 2020, there were approximately 3 million Aquilaria trees spread over 3,000 hectares, with an average density of 1,000 trees per hectare and over 9,000 households growing Aquilaria.