Researchers have discovered a method to refine rare earth minerals from discarded devices using a chemical compound commonly employed in medicine. They claim that their method offers numerous environmental benefits.

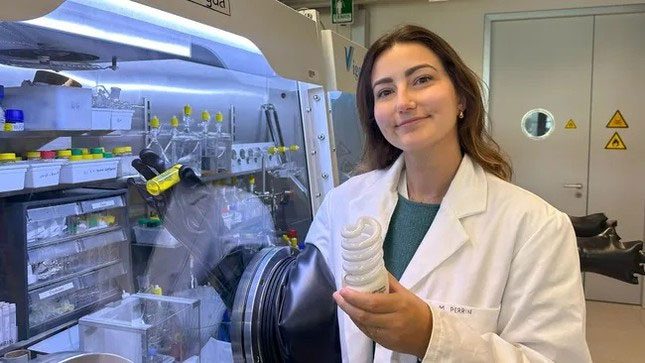

ETH PhD student Marie Perrin presents a new recycling method. In her left hand, she holds raw materials in the form of a fluorescent lamp, and in her right hand, she holds a yellow reagent that can separate rare earth metals. (Photo source: Fabio Masero / ETH Zurich).

Rare earth minerals, also known as rare earth metals or rare earth elements (REE), include materials such as europium, yttrium, and samarium, and have various applications in electronics. They are commonly found in smartphones, computers, televisions, and even electric vehicle batteries.

REEs are actually quite abundant but occur naturally at low concentrations within compounds in ores. This means that to be isolated for use, they must undergo multiple extraction and refinement steps, which are both chemically intensive and energy-consuming. In total, processing one ton of rare earth minerals generates approximately 2,000 tons of toxic waste.

Safer Mining and Recycling

The first author of the study, Marie Perrin, a PhD student at ETH Zurich, explained that existing separation methods for recovering europium have so far been impractical. However, the research team has harnessed small inorganic molecules known as tetrathiometallates, which consist of four sulfur atoms surrounding tungsten or molybdenum.

Scientists note that tetrathiometallates are transition metals commonly used in medicine to treat copper metabolism disorders and cancer. By using them as reagents in a redox reaction, they can easily extract europium samples, including from post-consumer waste such as used energy-saving light bulbs.

They crush the bulbs and then dissolve them in trifluoromethanesulfonic acid. After filtration, they vacuum dry the remaining residue at 200 degrees Celsius and then add it to a tungsten tetrathiometallate solution. The scientists further stated that the europium removal efficiency reaches approximately 98.9%—significantly higher than the best-reported methods currently available.