The uranium extraction plant from seawater could be fully operational within the next decade, meeting China’s substantial demand for uranium.

Construction work could begin as early as 2026. Once completed, the plant is expected to extract tons of uranium annually from seawater, which is believed to have uranium reserves that are 1,000 times higher than those found underground. The Chinese Academy of Engineering Physics, the agency responsible for nuclear weapon development, is overseeing the project with support from research institutions like the Chinese Academy of Sciences.

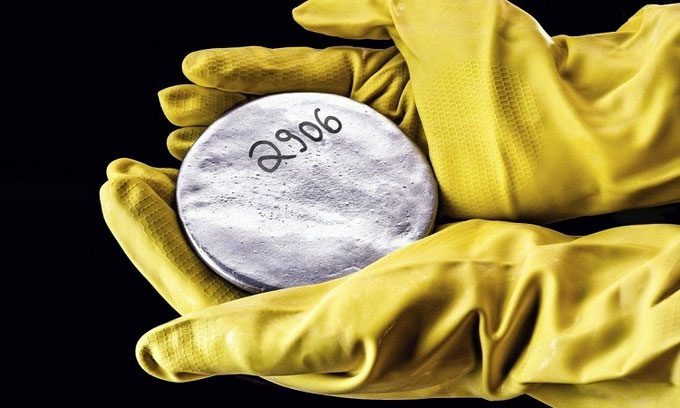

Uranium is very difficult to extract from seawater. (Photo: Shutterstock).

“The nuclear industry is a strategic high-tech industry and a crucial foundation for national security. The uranium source plays a key role in the nuclear fuel cycle system,” said Cao Shudong, General Director of the China National Nuclear Corporation, on May 10.

China is facing a uranium shortage with reserves at only 170,000 tons, which is lower than that of France. With a construction pace of 6 to 8 nuclear reactors per year, China will require approximately 35,000 tons of uranium annually by 2035, indicating that the country’s reserves could be depleted within the next five years. If this occurs, China will have to rely on imported fuel. However, the global supply chain can be volatile amid political tensions.

According to experts, uranium security threatens China’s plan to become the world’s largest nuclear power producer by 2030. Technical details regarding the construction of the uranium extraction plant have not been disclosed. Nevertheless, researchers worldwide have made significant achievements in turning this idea into reality. For example, the efficiency of uranium-absorbing materials has increased more than 30 times since the 1960s, according to recent research from Tsinghua University.

“Developing seawater uranium extraction technology will help ensure a stable uranium supply for future nuclear energy development,” emphasized Professor Ye Gang and colleagues at the Institute of Nuclear and New Energy Technology in a study published in March in Tsinghua University’s journal.

Que Weimin, Secretary-General of the China Seawater Uranium Extraction Technology Advancement Alliance, noted that there are still many technological challenges. Although the pilot plant is expected to be operational by 2035, the uranium supplied by the plant will likely be more expensive than what nuclear power plants can afford. The timeline for moving towards commercial production is set for 2050, as this technology is as challenging as constructing an artificial sun. Uranium in seawater exists in very small quantities. This radioactive element also bonds with oxygen and carbon in a relatively stable form, making it difficult to interact with other chemicals, thus complicating the uranium extraction process.

Scientists in China and many other countries have devised various solutions. The most viable absorbing material currently is amidoxime, a chemical compound that can attract floating uranium particles. To enhance efficiency, researchers combine amidoxime with other materials ranging from rare earth elements to proteins to strengthen the bonding. However, the costs of this technology remain high. In field experiments, materials may also incorporate other minerals from seawater, such as vanadium. The cost of extracting 1 kg of uranium from seawater can exceed $1,000, which is ten times the cost of mining it from the ground.