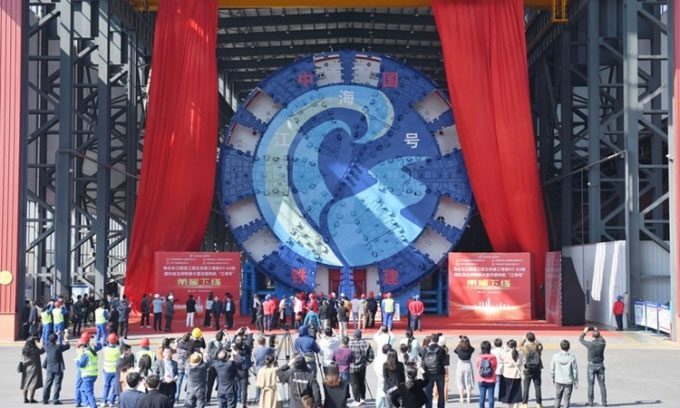

The 16.64m Diameter Tunnel Boring Machine Will Construct a Tunnel Beneath the Yangtze River in Jiangsu Province.

China has completed the production of the largest tunnel boring machine (TBM) in the world with a diameter of 16.64m. The machine, named Jiang Hai, weighs 5,000 tons and is 145m long. This is also the largest tunnel boring machine designed in China. The machine was manufactured in Hunan Province, through a collaboration between the China Railway Heavy Industry Group (CRCHI) and the China Railway 14th Bureau Group, as reported by Interesting Engineering on November 1.

The tunnel boring machine launched in Changsha. (Photo: Global Times).

This TBM has a cutting head diameter equivalent to a 5 to 6-story building. Zhao Hui, the president of CRCHI, stated that this development milestone marks a significant achievement in the industrialization of large-diameter tunnel boring technology over 16m in China. The design of the machine focuses on operations in fault zones, capable of withstanding sudden inflows of muddy water. Its ring-shaped cutting head allows for excavation in extreme conditions, while the dual operating mode enables simultaneous drilling and blasting, improving speed and efficiency.

The hollow cutting head facilitates easier navigation in complex geological conditions. Researchers at Tsinghua University have expanded the applications of this machine in irrigation, hydropower projects, mining, and infrastructure. According to test results, the performance of the hollow cutting head can increase by 30% after processing fractures in ultra-hard rock layers.

The new TBM will be used to construct a tunnel across the Yangtze River in Jiangsu Province, connecting Nantong and Suzhou. This tunnel is part of a 39 km highway project expected to be completed by 2028. Stretching approximately 11.2 km beneath the Yangtze River, the tunnel will reach a depth of 75 meters.

According to You Shaoqiang, the chief engineer of the project at China Railway 14th Bureau Group (CR14G), the tunnel faces numerous challenges due to groundwater, soft soil, and sludge, making conventional tunneling methods impractical. The advanced TBM is expected to operate at a speed of 12-16 meters per day, with the tunneling process lasting about 2.5 years. Since the tunnel is located near the mouth of the Yangtze River, precision must be within about 1 cm to ensure the safety of the river dams.

Previously, in 2022, CRCHI and CR14G co-produced a 16.07m diameter TBM for a renovation project in Beijing. According to senior engineer Fan Ruiqiang, they took over two years to develop the new, larger TBM. This machine is also smarter, with a database that records past tunneling issues, allowing it to provide suggestions to operators when similar challenges arise.