A group of scientists is utilizing waste materials such as fly ash and bottom ash from waste-to-energy power plants, along with recycled glass, to create concrete that can transmit light. This innovation has earned them third place in the 2024 Science Initiative competition.

The product was developed and tested by the “Green” Concrete Group from the University of Mining and Geology. The standout feature of this green concrete is its excellent light transmission capability, high strength, and the complete absence of cement. This type of concrete is unprecedented in the Vietnamese market, particularly due to its use of recycled glass as the light-transmitting material, which replaces the expensive optical fibers used in existing luminous concrete worldwide.

Associate Professor Dr. Mai Anh Tuan, head of the jury for the 2024 Science Initiative competition, awards the third prize to the author group. (Photo: Ngoc Thanh).

In an interview with our reporter, Dr. Tang Van Lam, 41, a representative of the research group, shared that the project commenced in early 2021 with the goal of alleviating the pressure of waste treatment and utilizing industrial waste, particularly ash and slag from thermal power and metallurgy plants. This initiative aims to minimize cement use and reduce the impact of toxic gases and dust during cement production. The research also addresses the scarcity of green materials for construction projects.

The group proposes a technology that reuses fly ash, bottom ash, and sludge from water treatment plants combined with recycled glass. By maximizing the use of solid waste, especially using recycled glass beads to allow light to pass through, the production cost of the product is reduced. The green concrete made from ash, slag, and sludge completely replaces cement while maintaining excellent mechanical properties, with compressive strength reaching up to 60 MPa based on 10 cm cubic sample tests.

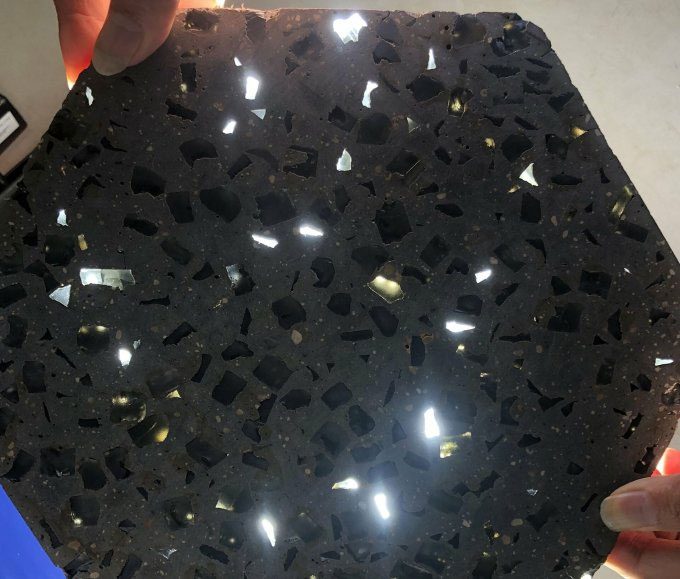

The light-transmitting green concrete panel created by the research group. (Photo: Research Group).

The product is manufactured in thin panels, available in square, rectangular, or hexagonal shapes, with a thickness ranging from 10 mm to 15 mm. The concrete surface is smoothed and polished, a crucial process that determines the visibility of the recycled glass beads embedded in the concrete. The quality of light transmission is also entirely dependent on this process. The recycled glass beads facilitate the passage of both natural and artificial light through the concrete panels.

According to Dr. Lam, a challenge in the research is that the sharp edges of the recycled glass beads could pose safety risks to users. To mitigate this, the team applied a layer of liquid glass on the surface to enhance aesthetics and safety.

The light-transmitting green concrete is considered useful for decorative structural applications in buildings, widely applicable in both interior and exterior design, creating unique architectural effects in terms of color and light.

However, this product still has some drawbacks, such as the inability to create light patterns. In the future, the group intends to continue researching new manufacturing methods to produce materials capable of transmitting light in specific directions, resulting in improved lighting effects.

The experimental shaping process in the laboratory. (Photo: Research Group).

Evaluating the project, Dr. Hoang Minh Duc, Director of the Institute of Concrete Specialty at the Institute of Construction Science and Technology (IBST), stated that the research provides a novel approach to simultaneously handling various waste types to create new products. He suggested that to further improve the product, the group should delve deeper into the interaction mechanisms among the components, the ability to isolate harmful substances from the waste materials involved, and optimize technology based on the desired properties, especially light transmission capabilities. “In terms of market application, the group should initially focus on utilizing this material for decorative and artistic products, including integrating it with traditional materials,” he stated.

The solution proposed by the “Green” Concrete Group from the University of Mining and Geology received the third prize worth 30 million VND at the 2024 Science Initiative competition organized by VnExpress. Associate Professor Dr. Dao Van Duong, a member of the jury, recognized the product’s usefulness in decorative structures within construction projects while also noting that the green technology contributes to the sustainable “green” transformation agenda. He praised the creative idea of using glass for light transmission but advised the group to conduct more in-depth research on the waste material market and adopt a scientific approach to assess the strength and light transmission value of the product.