Football players will soon receive their first pairs of shoes custom-made to fit the exact shape of their feet, thanks to a new 3D technology that inventors hope to bring to market soon.

The shoes are designed layer by layer using a new 3D printing technique, where a laser beam fuses nylon material particles together.

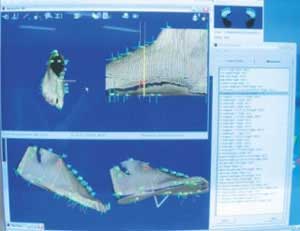

First, a laser device will capture a cross-sectional image of the player’s foot to create a three-dimensional model. Following this, the player performs a series of movements with a special insole in their shoes to demonstrate the pressure points on their feet.

|

|

First, the foot is cross-sectioned to produce a three-dimensional digital model. (Image: blogs.zdnet) |

The information obtained will be combined with a detailed analysis of the player’s walking patterns, as well as the structure of their feet and calves, to create a shoe sole tailored to their specific measurements and the arrangement of the studs on the sole.

|

|

And this is the foot model that will help create your perfect shoe. (Image: blogs.zdnet) |

The final design is then printed using a 3D process called selective laser sintering, developed by Siavash Mahdavi from Complex Matters.

Instead of producing shoes based on uniform forces, Mahdavi’s software allows for the creation of soles with varying thickness and durability at different locations, matching the human foot and enhancing the material’s ability to withstand impact.

“This design gives players the best chance to reduce injuries,” said Greg Lever-O’Keefe, co-founder of Prior2Lever, a company that plans to introduce this service to professional sports in April, based in London.

It is hoped that if the system operates perfectly, it could be made available in stores, allowing a pair of shoes to be printed to fit a customer’s feet in just a few hours.

T. An