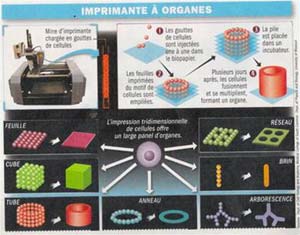

Thanks to a printer that can spray… cells onto a piece of biological paper, it won’t be long before various types of organs can be created as desired. This research project from the United States opens up a promising perspective.

|

|

Human Organ Printer |

Under the leadership of biological physicist Professor Gabor Forgacs from the University of Missouri, Columbia, and with a grant of $5 million from the National Science Foundation, researchers from three universities are developing biological inks and papers that can… print human organs!

So far, they have successfully created tubes resembling human blood vessels and cardiac cell sheets in three-dimensional space using a special printer. According to Glenn D. Prestwich, a professor at the University of Utah and a collaborator in producing biological paper, in about 5 to 10 years, humans will be able to print organs.

The initial focus is on researching the potential for biological self-assembly in the laboratory, similar to fetal development. They have experimented with printing DNA and RNA molecules on a flat surface, then sought ways to print additional cells. The process is as follows: first, a small piece of biological paper is created, which is a mixture of gelatin and hyaluronic acid (a component that surrounds cells, aiding in their movement and reproduction).

The biological ink consists of cell foam, measuring a few hundred microns (1/1,000 mm), which is then printed onto the paper (see diagram). Multiple layers are printed on top of each other until the desired height is achieved. For instance, to create a 2 cm long tube resembling a blood vessel, enough layers are printed to reach a thickness of 2 cm. Each layer forms a ring shape, representing the cross-section of the tube. This entire stacked structure will be placed in an incubator, allowing the cells to merge and multiply, developing further.

The biological paper serves merely as a scaffold to connect and nourish the cells. Gradually, it will dissolve as the organ takes shape. Professor Forgacs notes: “Printing each ring shape on the biological sheet takes less than 2 seconds, but it takes a week for the cells to fuse together. We have been able to print vascular tubes directly.”

|

|

Professor Gabor Forgacs |

According to Helen Lu, head of the Department of Biological Materials at Columbia University, organ printing could become a reality in the near future. However, she insists that scientists must accurately control other parameters, such as the mechanisms for forming blood vessels beneath the skin. It cannot simply be grafted into the body and considered… done! Researchers are well aware of the challenges that lie ahead. Forgacs has refrained from commenting on the future of this technology.

The research team in London, led by Professor Suwan Jayasinghe, was the first to print mouse brain cells. This technology, when applied to humans, would allow for the replacement of damaged brain regions by “casting” cells as desired! However, to print it, the ink must be living cells measuring only a few microns, while current ink sizes exceed 1 mm.

The British scientists have employed a technique called “electro-hydrodynamic printing,” which creates a strong electric field for the cell-containing solution as it exits the nozzle. The charge of the solution interacts with a magnetic field located behind the nozzle. The liquid is dispersed into extremely fine droplets upon contact with the biological paper.

Although cells are subjected to an electric field of up to 30,000 volts along a distance of 1.5 cm without any adverse effects, long-term safety still needs to be evaluated. Professor Brian Derby from the University of Manchester believes: “The crucial issue in this technique is to determine which types of cells can be three-dimensionally printed and remain viable for a considerable duration.”

DINH CONG THANH