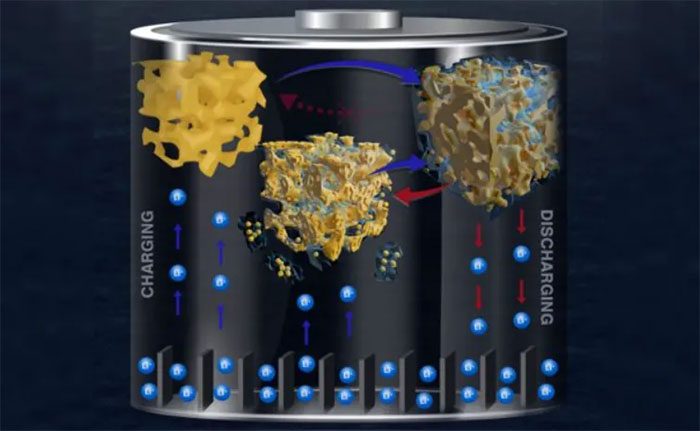

A research team from Stanford University and the SLAC National Accelerator Laboratory has recently announced the discovery of the cause of short-circuiting, a phenomenon that periodically occurs in lithium metal batteries with solid electrolytes.

Next-generation lithium batteries will charge faster and last longer.

This long-term solution could help humanity overcome barriers to the global use of electric vehicles. The newly published research details various experiments that describe how nanoscale defects and mechanical stress can damage solid electrolytes. Additionally, dust or other impurities that occur during production can also cause battery malfunctions.

The research team believes that the problem is caused by mechanical stress during battery recharging. “Even a slight dent, bend, or twist of the battery can cause nanoscale issues in the material to open up, allowing lithium to penetrate the solid electrolyte and lead to short-circuiting.”

Throughout more than 60 experiments, researchers demonstrated that ceramic materials develop “cracks, dents, and fissures at the nanoscale, many of which are less than 20 nanometers wide.” According to the team, these existing cracks will open up during fast charging, allowing lithium to infiltrate.

The team achieved these results by inserting an electrical probe into the solid electrolyte, creating a miniaturized battery, and using electron microscopy to observe the fast charging process in real time. They employed an ion beam as a “scalpel” to analyze the reasons behind lithium accumulation in certain parts of the ceramic material. From this, they discovered that when the pressure of the electrical probe increases, “simulating the mechanical stresses of dents, bends, and twists increases the likelihood of the battery short-circuiting.”

The research has shown that even a slight bend, a gentle twist, or a dust particle caught within the electrolyte can cause the battery to fail. These results will enable developers to design suitable materials to prevent short-circuiting.