3D Ink Made Entirely from E. coli Bacteria Creates Sustainable Structures with Self-Healing Properties.

American scientists have developed a type of living ink made entirely from bacteria. This bacterial ink flows like toothpaste under high pressure and can be 3D printed into various shapes, including circles, squares, and cones. All these shapes maintain their form and have a shiny appearance.

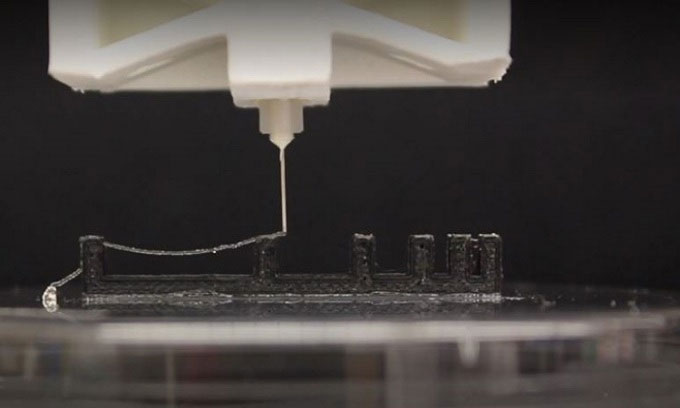

Experiment placing ink strands on small columns. (Photo: Nature Communications)

The research team described the composition of the 3D ink containing bacteria in a paper published on November 23 in the journal Nature Communications. This new ink is still under development but promises to become an important renewable building material that can self-heal, making it ideal for sustainable housing on Earth and in space.

Previously, scientists had created various printable gels combining bacteria and polymers. One type of ink contained hyaluronic acid, extracted from seaweed and smoked silica, which made the material thicker and more viscous. However, the new material does not contain polymers and is produced entirely from genetically modified E. coli bacteria. The research team used a culture medium made from live bacterial cells for the ink to grow. When harvested from the liquid culture, the ink becomes jelly-like, enabling it to be fed into a 3D printer to create living structures. These structures do not grow further and retain the printed shape.

Bacteria are crucial components in many products such as perfumes and vitamins. Researchers have modified bacteria to produce biodegradable plastics. According to Neel Joshi, a synthetic biologist at Northeastern University and co-author of the study, the bacterial ink is at the forefront of the field of genetically modified living materials. Unlike structures made from concrete or plastic, living systems automatically adjust to their environment and have the ability to regenerate.

Typically, bacterial inks rely on a polymer framework to solidify. However, polymers have their limitations and can unintentionally alter the mechanical properties of the ink. Additionally, polymers must be biocompatible so that the bacteria do not die. Synthetic polymers like polyethylene are often derived from oil and are not renewable.

Many genetically modified living materials exist in the form of hydrogels, which can absorb large amounts of water. In 2018, Joshi and Anna Duraj-Thatte, an engineer at Virginia Tech, successfully created a hydrogel entirely from E. coli that could grow and regenerate. Although this hydrogel could be passed through a syringe, it was not strong enough to support its own weight, thus preventing the formation of any structures.

The research team needed to solidify the material. They genetically modified E. coli to produce protein polymers from fibrin, designed to link into a mesh-like network. This modification allowed the material to harden enough for printing while still being able to flow from the nozzle of the 3D printer. The researchers brought the 3D ink to the lab of Yu Shrike Zhang, a biological engineer at Harvard Medical School.

There, they printed the bacterial ink in various patterns and designs to test its ability to maintain its shape. The ink flowed like toothpaste from the printer but did not collapse after printing and passed all tests. They also examined how much the ink strands could stretch without breaking. In the experiment, the printer’s nozzle released strands of ink half a millimeter thick across a row of columns spaced apart. As a result, the ink strand was able to support its own weight between the columns, which were 156 mm apart.

While the bacterial ink still needs further development due to its tendency to dry out and lack of stability for constructing larger structures like human housing, researchers are seeking ways to make the 3D printed structures more robust. However, they emphasize that the potential applications of this ink in the future are limitless.