A research team at the University of Texas has developed an enzyme that effectively breaks down PET plastic at temperatures between 30 – 50 degrees Celsius and across various pH levels.

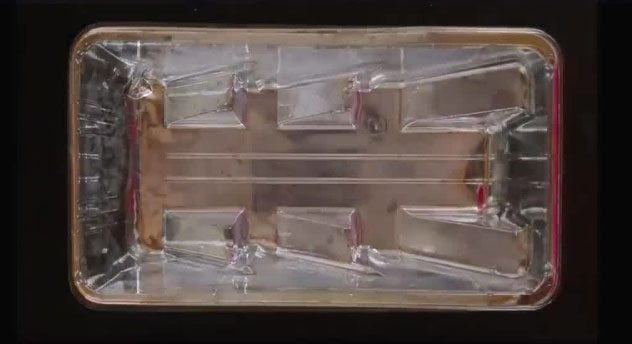

The University of Texas enzyme breaks down a type of plastic in 48 hours. (Video: Cockrell School)

The use of enzymes to decompose plastic waste has been making significant breakthroughs, showing increasingly high efficiency and the ability to convert materials into simpler molecules. A study published in the journal Nature on April 27 marks another advancement as a team of experts at the University of Texas (USA) utilized machine learning technology to create an enzyme capable of breaking down certain types of plastic in just 24 hours, with high stability suitable for large-scale application.

Scientists have explored the potential of enzymes in aiding plastic recycling for over a decade, with notable advancements occurring in the last six years. In 2016, Japanese researchers discovered a type of bacteria that used enzymes to break down PET plastic in a few weeks. PETase, a modified version of these enzymes, further improved efficiency. In 2020, scientists developed an even stronger version capable of digesting PET plastic at six times the speed.

The research team at the University of Texas aimed to address some limitations of existing enzymes. They noted that the application of this method was hindered due to poor performance at low temperatures and varying pH levels, lack of effectiveness in directly addressing untreated plastic waste, and slow reaction rates.

The new enzyme shows superiority in breaking down PET plastic at temperatures from 30 – 50 degrees Celsius

The team developed a machine learning model that can predict which mutations in the PETase enzyme would enhance its capabilities. They meticulously studied various PET products, including containers, water bottles, and fabrics, then used the model to design and produce a new improved enzyme named FAST-PETase.

The new enzyme demonstrates superior performance in breaking down PET plastic at temperatures between 30 – 50 degrees Celsius and across various pH levels. It can almost completely break down 51 different untreated PET products within a week. In some experiments, it even required only 24 hours to decompose plastic. The scientists also validated a closed-loop PET recycling process, where FAST-PETase breaks down plastic, allowing for the recovery of monomers to chemically recreate the material.

“When considering solutions for environmental cleanup, you need an enzyme that can operate at normal ambient temperatures. This is what gives our technology a significant advantage for the future,” said study author Hal Alper.

The new technology has the potential to rapidly decompose plastic waste at low temperatures. Therefore, the research team believes they have found a mobile, affordable solution that can be applied on an industrial scale. They have filed a patent for the new technology and hope it will be utilized at landfills and polluted areas.