One of the largest mining companies in the world is digging through drawers, old phones, and landfills across the United States to find valuable “red gold.” This refers to the copper scraps that meet the growing demand for energy transition.

Shredded mobile phones, computer cables, and crushed old cars are piled up to over 9 meters high outside the 97-year-old Glencore copper smelting plant. This facility is located deep in a sparsely populated forest area in northern Canada. There, scrap is melted down, and copper is concentrated to produce new metal sheets.

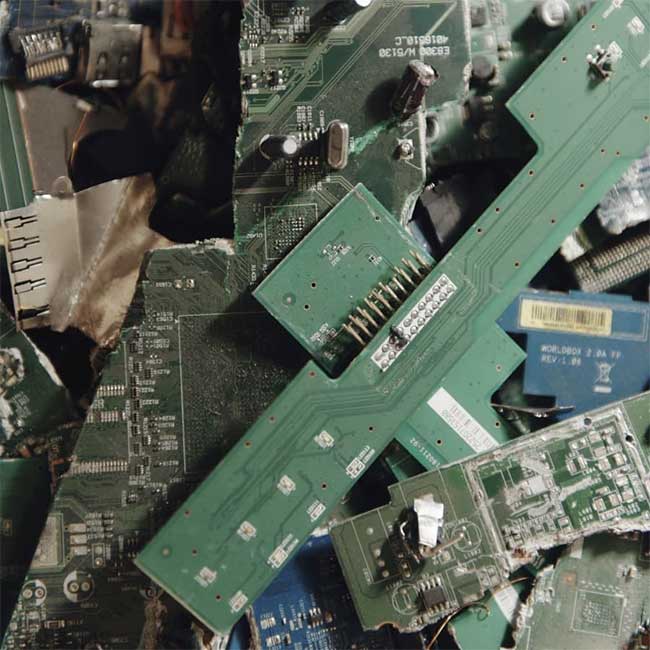

Old electronic devices have become inputs for the smelting plant. Currently, Glencore and other copper producers are expanding their scrap procurement efforts to increase recycling capacity.

Strengthening the transition from fossil fuels to renewable energy promises to reshape the commodities market. If the United States needs less crude oil and coal, it will require more lithium for electric vehicle batteries as well as for large power poles. Copper is an essential material in everything related to electricity.

Kunal Sinha, Glencore’s recycling director, stated: “In the next 25 years, we will consume more copper than humanity has consumed in total so far.”

Old electronic devices have become inputs for the smelting plant.

The demand for copper has skyrocketed in recent decades due to China’s modernization efforts. Legislation promoting renewable energy development in the U.S. has also increased demand for the red metal. Data centers being built to support artificial intelligence (AI) also require copper. Smartphones do as well.

Glencore estimates that global copper supply must increase by approximately 1 million tons per year until 2050. This will require additional copper equivalent to the world’s largest mine, Escondida in Chile, each year.

The Value of Scrap

Even when large copper deposits are found, it can take decades to bring those metal mines into operation. Tom Mulqueen, a strategist at Citigroup, noted that this prevents mining companies from keeping up with new demand, forcing the market to turn to scrap.

Unlike oil or food products, copper can be recycled indefinitely. A significant amount of copper is lying in scrap yards and landfills. As prices rise, recyclers are increasingly motivated to reclaim these materials. Copper prices are currently at an all-time high.

However, demand may fluctuate due to a sluggish Chinese economy, declining production, or stalled energy transitions.

Unlike oil or food products, copper can be recycled indefinitely.

According to estimates from energy data firm Wood Mackenzie, nearly half of the demand will be met by recycled copper by 2050, up from the current one-third ratio. A significant amount of U.S. scrap is shipped to Asia, but copper producers are building recycling capacity in North America.

The German company Wieland began constructing a $100 million recycling facility in Shelbyville, Illinois, in 2022. The company is negotiating with the Department of Energy for an additional $270 million in funding for the facility’s expansion.

Another German company, Aurubis, is building an $800 million recycling facility in Augusta, Georgia. A spokesperson stated that the company has begun sourcing scrap and expects to produce copper by next year.

The Global Search

Traders from Glencore in Toronto, Switzerland, and New York are tasked with sourcing scrap. Materials from about 40 countries are brought to Rouyn-Noranda and then transported to Glencore. In fact, the smelting gate even has a trash bin for the 42,000 residents nearby to collect old wiring and broken appliances.

The company is also searching at auto junkyards. Usable parts and metal will be extracted from cars before they are shredded. Glencore has discovered that the amount of copper found in auto junkyards can be twice that of copper in geological mines.

The amount of copper found in auto junkyards can be twice that of copper in geological mines.

The scrap piled up in Quebec is shredded further and sent into a 1,200-degree Celsius smelting furnace. Ultimately, the molten metal will be cooled and transferred to Glencore’s Montreal refinery. There, it will be melted down again to extract other metals such as platinum, palladium, silver, and gold.