Using chitosan from shrimp shells and alginate from seaweed, Master Vu Thanh Binh creates an artificial bone framework to restore missing bone parts.

Master Binh (34 years old) currently works at the Laboratory of Tissue Engineering and Regenerative Medicine, Faculty of Biomedical Engineering, International University (Vietnam National University, Ho Chi Minh City). He and his research team have successfully developed a scaffold that helps bone cells adhere, proliferate, and mineralize to restore defective bone areas.

Master Binh explained that natural bone tissue in the body contains polymer components, which are bundles of collagen fibers and hydroxyapatite (calcium phosphate). These components form a load-bearing bone tissue structure that supports functions such as providing support and forming the bone marrow cavity. Based on this foundation, the team created natural polymers using chitosan from shrimp and crab shells, along with alginate material derived from seaweed.

Chitosan and alginate are combined with a polymer found in synovial fluid, hyaluronic acid, which enhances elasticity and reduces damage to joint surfaces. “These three materials need to be linked together to form an artificial bone framework“, said Master Binh. The bone scaffold created in the laboratory resembles natural bone tissue as closely as possible.

According to the team, linking the materials can involve the use of additives. However, this method has the disadvantage of leaving residues of exogenous crosslinking agents, which may be cytotoxic to bone cells. Therefore, the research group implemented a method to modify the structures of the materials by adding functional groups, enabling them to self-link without the need for additives.

Master Vu Thanh Binh inspects the 3D bioprinter used for creating the artificial bone framework with gel-based ink. (Photo: Ha An).

From the gel-like material, the hardened bone framework creates a porous structure that allows natural bone tissue cells to adhere and proliferate. This artificial bone framework is biodegradable (it disappears after human bone cells adhere and grow). These bone cells can secrete a matrix to create their own framework to fill in the missing bone area. Depending on the characteristics and location of the bone defect, the team can adjust the biodegradation time to match the time it takes for bone cells to secrete and create the bone framework.

According to Master Binh, depending on the type of bone and the volume of lost bone, bone cells require several months to years to regenerate a new framework and completely restore the defected area.

The artificial bone material developed by the research team is derived from natural sources and exists in gel form. (Photo: Ha An).

The team conducted experiments on mice by anesthetizing them, drilling a spot on the skull to create a bone defect without harming their brains. They then injected the gel into the area of the bone defect. Once the mice regained consciousness, their survival metrics such as weight, diet, and movement were monitored for a month.

The author noted that because the gel material can fill the defect area in any shape, it hardens quickly and initiates the process of forming an artificial bone framework. After a month, the team humanely euthanized the mice and performed brain surgery to assess the ability to regenerate bone tissue based on the artificial bone framework using histological staining methods. The results showed an 80-90% fill rate in the defected area on the mice’s skull, with high biocompatibility.

This result lays the foundation for the team to test on larger animals with conditions more similar to humans, reinforcing scientific evidence for potential human application. However, according to Master Binh, there is a significant gap between animal models and human application, requiring several processes, procedures, and ethical review boards to demonstrate the efficacy and safety of the product.

In the short term, the research team aims to develop the gel into a commercial bioprinting ink. Once bioprinted, the gel can form artificial bone frameworks for research in the biomedical field and animal testing, replacing high-cost imported products.

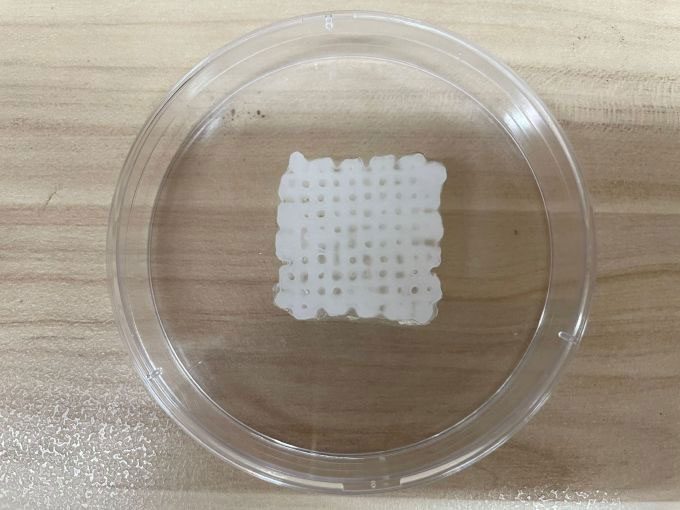

The shape of the artificial bone after being printed from a 3D bioprinter. (Photo: Ha An).

According to Associate Professor Dr. Nguyen Thi Hiep, Head of the Biomedical Engineering Department at International University (Vietnam National University, Ho Chi Minh City), the research direction of artificial bone from natural materials has been pursued by scientists worldwide for over a decade. In Vietnam, there have been several studies conducted at institutes and universities, aiming to personalize the treatment of bone injuries in humans. This addresses the issue of treating with pre-existing bone frameworks, which in many cases are not suitable for individuals. The gel created by the team, once injected into the bone defect area, can shape and adapt to any individual.

However, Associate Professor Hiep believes that further studies need to be conducted on larger animals to evaluate safety and feasibility on larger bone sizes, progressing towards clinical trials on humans. “With this research, we are seeking funding sources to conduct larger-scale trials, perfecting technological solutions to contribute to the field of precision medicine in the country,” stated Associate Professor Hiep.