By applying a layer of “liquid metal” to the surface of fabric, Dr. Truong Vi Khanh and his team from Flinders University (Australia) have successfully developed a smart material that can self-heal and monitor heart rates.

Dr. Truong Vi Khanh, Deputy Director of the Biomedical Nanoengineering Laboratory at Flinders University, leads the research team. He recounts that in 2018, while watching the movie “Terminator,” he suddenly had the idea of creating liquid metal capable of changing shape.

He reached out to Professor Michael Dickey from North Carolina State University (USA), a leading scientist in liquid metal research, to propose the idea of liquid metal particles that can change shape and kill bacteria upon contact. This idea later received awards from Fulbright and RMIT, allowing him and his colleagues to conduct their research.

The team collaborated with scientists from North Carolina State University and Sungkyunkwan University (South Korea) to create a compound of gallium and indium that can form electronic circuits within the fabric. These fabric layers with electrical circuits are applied to develop smart wearable devices. “We can customize the electrical pathways as desired by adding multiple layers that can enhance the fabric’s conductivity,” Dr. Khanh stated.

The team also successfully created self-healing electrical pathways when cut, thanks to the formation of new conductive paths along the edges of the cut, thus providing self-repair functionality. This ability makes the material useful in circuit connections and flexible electrodes for measuring electrocardiogram (ECG) signals. The researchers transformed the coated fabric pieces into electrodes for ECG machines to monitor heart rates. The testing process yielded results that performed as well as commercial gel-based electrodes.

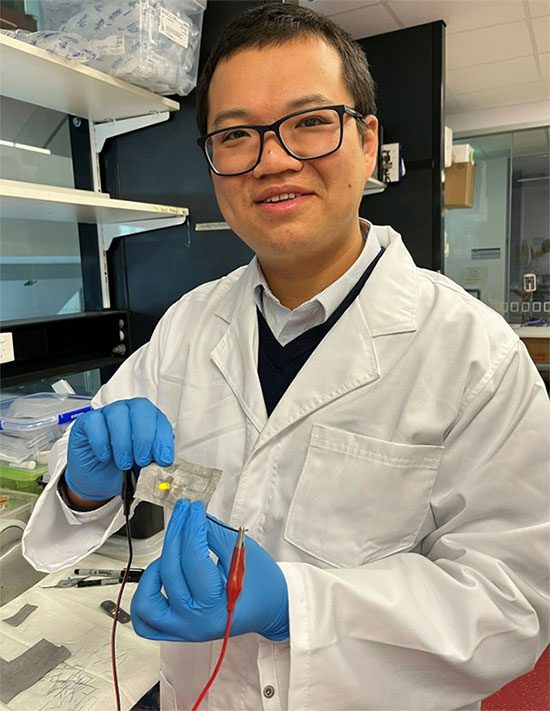

Dr. Truong Vi Khanh introduces the metal-coated fabric. (Photo: NVCC)

Test results also showed that the metal-coated woven fabric has effective antibacterial properties. This fabric helps repel pathogens and can be used for longer periods without washing, making it suitable for hospital bed sheets and patient clothing to prevent infections.

Dr. Khanh added that gallium and indium are not abundant metals, but the manufacturing process for the liquid metal-coated fabric requires less than one micrometer of each in the fabric coating. “Due to the small amount of material used, the manufacturing process is cost-effective,” he informed.

The work was published in the journal Advanced Materials Technologies at the end of May.

Dr. Truong Vi Khanh (left) with researcher Nguyen Tien Thanh in the laboratory at Flinders University (Australia). (Photo: NVCC).

Professor Michael Dickey praised this research as groundbreaking in applications related to liquid metal and liquid metal coatings. The authors innovatively combined knowledge of materials and nanotechnology to create unique methods.

“This groundbreaking research is particularly significant in developing new antibacterial technologies,” stated Professor Krasimir Vasilev, Director of the Biomedical Nanoengineering Laboratory, to the press.

Dr. Khanh hopes to expand research collaborations and provide opportunities for Vietnamese students to access global technologies. Currently, his laboratory has eight Vietnamese students pursuing their Ph.D. degrees.

| Dr. Truong Vi Khanh received his Ph.D. in nano-biotechnology in 2012 from Swinburne University. He has held various positions, including RMIT VC member and Fulbright Scholar, before working at Flinders University. As an expert in antibacterial material applications in healthcare and industry, Dr. Khanh has successfully collaborated with businesses on research projects, creating highly applicable products in healthcare and industry. He has published over 150 scientific works with 8,000 citations (averaging more than 60 citations per article). |