A team of scientists from the Mekong Delta Rice Institute has developed a multi-functional seed sowing machine that can prepare land and sow seeds at a rate of 0.1 – 0.2 hectares per hour, replacing 10 laborers.

The research was led by Master Nguyen Ngoc Hoang, Head of the Department of Mechanization and Post-Harvest Technology at the Mekong Delta Rice Institute, along with his colleagues.

According to the research team, there are currently almost no seed sowing machines used for planting beans and corn on raised beds or rice fields in the Mekong Delta region. Meanwhile, the area dedicated to growing crops is decreasing due to rising manual labor costs and shortages. The team aims to create a new machine model to facilitate the transition of crop structures in vegetable production on rice land in Hau Giang and other southwestern provinces. “The product is aimed at comprehensive applications in 4.0 agriculture,” said Master Hoang.

Testing the operation of the multi-functional seed sowing machine by the research team. (Video: NVCC)

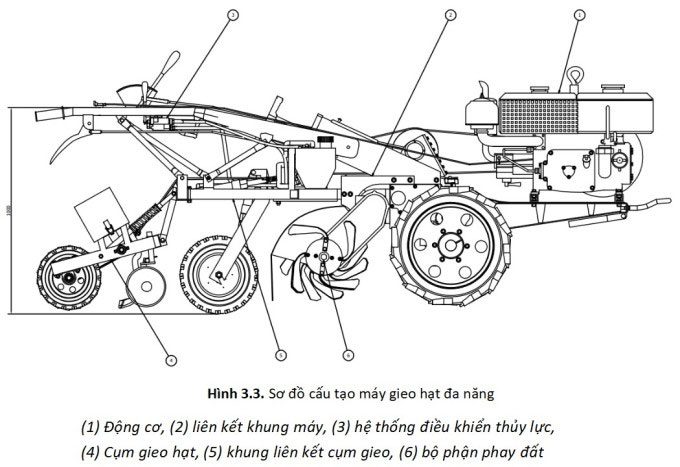

The multi-functional seed sowing machine consists of six main components: a 16 HP diesel engine, a machine frame, a hydraulic control system, a seed sowing unit, a connecting frame for the sowing unit, and a soil tilling section.

In its construction, the team utilized available components such as the diesel engine, agricultural gearbox, and movement system. The remaining parts focused on designing the row tilling component, sowing component, seed covering system, and lifting mechanism.

The machine is capable of simultaneously performing land tilling, row marking, seed sowing, and soil covering, with adjustable row spacing and seed types. Its advantages include a compact design and the ability to sow various types of seeds, including soaked corn seeds.

Before sowing, users need to determine the type of seed, row spacing, and density to select the appropriate sowing disc and adjust the row tilling distance and depth. While the machine operates, the tilling blades create ridges. The disc marks the row to create furrows between the tilled ridges. The sowing disc receives motion from the sowing wheel through a transmission system, causing it to rotate while the sowing holes receive seeds from the auxiliary compartment and deliver them to the seed release position. Here, a forced seed pushing mechanism prevents seeds from getting stuck in the disc holes. The seeds slide through the sowing tube and fall between the row marking discs, where a lever pulls soil over the seeds.

The machine has a working width of 1.2 meters, can sow from 2 to 4 rows with adjustable spacing of 300 – 800 mm, and a tilling depth of 30 – 100 mm. It has a missing seed rate (empty holes) of less than 3%, and the number of seeds per hole and spacing can be adjusted according to the type of sowing disc. The sowing productivity for corn is 0.1 hectares per hour (2 rows) and for soybeans is 0.2 hectares per hour (4 rows). The machine can replace about 10 laborers.

Design of the multi-functional seed sowing machine components. (Photo: NVCC)

Regarding machine operation skills, Master Hoang mentioned that users need not worry as the machine operates simply and is easy to handle. Farmers who have previously used land preparation machines will find it easy to operate after receiving instructions. However, users need basic mechanical training for effective maintenance and operation according to safety and technical standards. The estimated price of the multi-functional seed sowing machine is around 80 million VND.

According to Master Hoang, the machine’s advantage lies in its ability to sow various seed types, with adjustable density and spacing, but this requires users to spend time adjusting the arrangement of the tilling blades, row marking, and seed covering mechanisms in a straight line. To reduce the machine’s weight, the team did not design a driver’s seat; operators must walk behind the machine.

The machine has been tested in Can Tho and Hau Giang. However, Mr. Hoang believes that “more trials need to be conducted to evaluate its performance in other provinces.”

Engineer Le Trung Hieu, Director of Ewater Technology Company, stated that the product meets the mechanization needs of agriculture in the Southwestern region, helping to increase productivity and relieve labor. However, he noted that the tire-based mechanism allows operation only on dry land. In wet or marshy areas, the machine struggles to operate. He suggested that the authors modify certain structures, such as the wheel designs, to make it suitable for wet land operation. Additionally, the machine should be designed to be lighter for better mobility and easier transportation.