Researchers at the University of Cambridge, UK, have discovered a sustainable synthetic method for producing caprolactam, the precursor of nylon-6, from cyclohexanone.

|

|

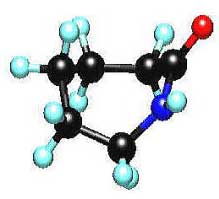

Caprolactam Molecule |

Nylon-6 is widely used in various industrial applications, with increasing demand. However, the current two-step process for producing nylon-6 from cyclohexanone relies on highly reactive substances, resulting in significant amounts of ammonium sulfate waste.

Caprolactam can now be produced through a one-step process, using no solvents, and utilizing air as the oxidizing agent, ammonia, and nanometer-sized porous aluminum crystals as catalysts.

These catalysts possess distinct acid and redox sites, allowing for the efficient conversion of cyclohexanone to caprolactam with yields reaching up to 78% at 80°C.

Robert Raja, one of the researchers, noted that the open structure of these bifunctional solids facilitates easy access for the substrate to active sites, and the products can easily diffuse out of the micro-porous structure.

Neville Hargreaves from Crystal Faraday, UK, mentioned that this innovation is indeed significant, but its success will depend on how it is applied on an industrial scale.