Lufthansa and BASF Develop AeroShark Film to Reduce Fuel Consumption and Emissions for All Aircraft.

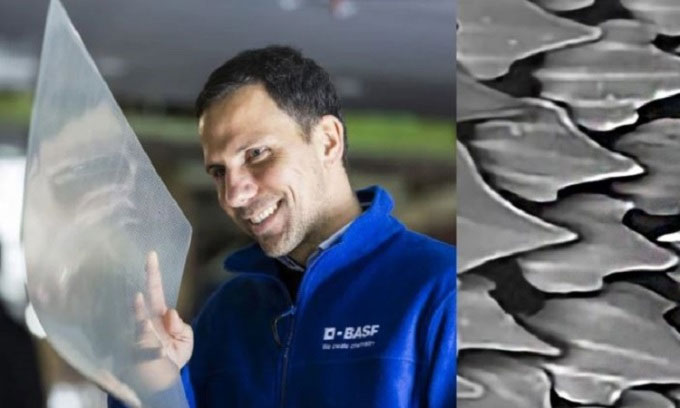

Millions of years of evolution have transformed the ocean’s most fearsome predator, the shark, from having smooth skin to having a slightly rough texture that reduces drag. Based on this characteristic of sharks, researchers have developed AeroShark for application on the surfaces of large aircraft.

AeroShark Film Layer. (Photo: Lufthansa Technik)

Millions of lens-shaped microstructures on the surface of the AeroShark film are no taller than 50 micrometers, yet they significantly impact fuel consumption. Swiss International Air Lines estimates that using 950 square meters of this film on a Boeing 777, aligned with the airflow around the fuselage and engine casing, could reduce drag and lead to a 1.1% decrease in fuel consumption.

As a result, Swiss International Air Lines has applied AeroShark film to all 12 of its Boeing 777 aircraft, saving 4,800 tons of jet fuel annually and reducing CO2 emissions by 15,200 tons. Previously, Lufthansa announced plans to implement the film on its cargo fleet and 10 Boeing 777 aircraft, resulting in a reduction of 3,700 tons of fuel and 11,700 tons of CO2 emissions each year.

The AeroShark development team noted that the film is slightly more effective on cargo aircraft that lack windows. They emphasized that the film is easy to apply, extremely durable against ultraviolet radiation, water, oil, high temperatures, and pressure changes on long-haul aircraft surfaces. AeroShark has been tested for over 1,500 flight hours on a Boeing 747-400. Using the film on wing surfaces also helps generate additional lift.

Lufthansa Technik and BASF are working to further develop the technology and apply it to various other types of aircraft. According to the research team, the sharkskin-inspired film could reduce fuel consumption and emissions by up to 3%.