The process of completing the installation of an undersea fiber optic cable can take several years, utilizing specialized cable-laying ships along a pre-surveyed route.

Google and Facebook have laid thousands of miles of fiber optic cables on the ocean floor, spanning across continents to bring the Internet to the entire world.

Typically, Google and Facebook will co-invest with several other companies for undersea fiber optic cable projects, although they also have their own individual projects. In total, Google has invested in 19 projects and owns 5 projects of its own.

Meanwhile, Facebook has invested in 2 operational undersea fiber optic projects, and they are also investing in 5 other projects currently under construction, according to a company representative.

To install fiber optic cables on the ocean floor, they first need to map out the route the fiber optic cable will take. According to Jayne Stowell, Google’s global infrastructure strategic negotiator, this can take several years.

Facebook told Insider that they will conduct geophysical surveys and depth measurements along the proposed cable route, allowing for precise planning down to the meter. To do this, the company must send out state-of-the-art equipped ships to survey the ocean floor, looking for risks such as strong currents, underwater landslides, and unexploded bombs or mines.

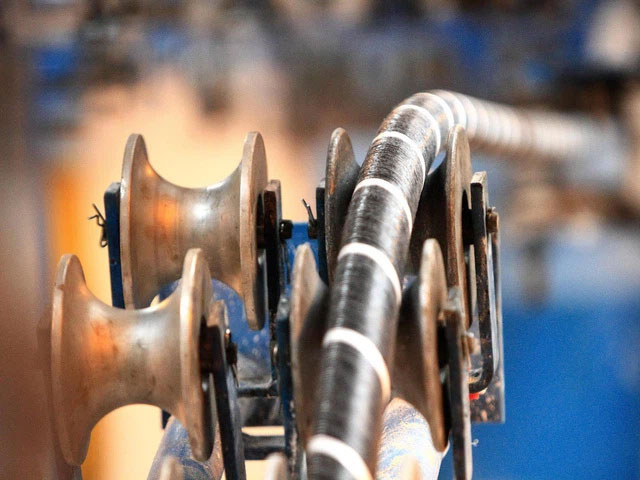

The cable itself is as thick as a garden hose.

They are wrapped in a copper sheath for electrical conduction. “A layer of plastic and steel is then added to waterproof it, allowing it to withstand adverse ocean conditions such as strong currents, earthquakes, or interference from fishing vessels,” Stowell said.

For Facebook’s 2Africa cable, aluminum is used instead of copper to reduce production costs. The 2Africa project, currently under construction, spans 37,000 km – just slightly shorter than the circumference of the Earth.

After manufacturing the cable and mapping the route, the cable is loaded onto a specialized laying ship. Stowell from Google stated that the company utilizes a fleet of 50 to 55 specialized ships, each with a crew capacity of up to 100 members. The loading of the cable onto the ship can take up to four weeks.

Meanwhile, the crew on Facebook’s cable-laying ship consists of about 30-50 people.

The ship departs the port, laying down the cable spool behind. Upon reaching deep water, it uses an underwater plow to dig a trench along the ocean floor where it lays the cable. The waves will quickly cover the trench after the cable is placed on the ocean floor.

“An undersea plow doesn’t look too different from a plow that a farmer might use in the field, except it is much larger – about the height of a two-story building,” Stowell said. This plow can only be used at depths of 1,500 – 2,000 meters.

This is the safest depth for undersea fiber optic cables, avoiding potential damage from fishing boats or anchoring vessels during storms. Essentially, undersea fiber optic cables will be laid naturally, without additional protective measures.

For long cables, manufacturers will add a component called an amplifier every 100 meters to keep the signal stable.

Although the fiber optic cable is made of the purest glass, over long distances, the intensity of the light beam begins to weaken. Amplifiers help boost the light intensity of the beam.

When reaching the destination, the cable-laying ship cannot approach the shore.

Buoys will be used to guide the fiber optic cable to shore, floating on the surface of the sea. Divers and smaller boats will be mobilized to carry out this task.

Finally, the cable is pulled onto the beach to a pre-made trench, where it is connected to a manhole on the beach, a container buried there where the undersea cable is connected to the onshore cable – which in turn connects to the cable station.